When your vehicle’s dashboard suddenly displays a drive train malfunction warning, it can be both alarming and confusing for drivers. This critical system error indicates that your car’s computer has detected an issue with one of the most essential components of your vehicle’s operation. Understanding what triggers this warning and how to respond can save you thousands in repair costs while ensuring your safety on the road.

The drivetrain system is the mechanical backbone of your vehicle, responsible for transferring power from the engine to the wheels. When a malfunction occurs, it affects everything from acceleration and fuel efficiency to overall vehicle performance. Modern vehicles are equipped with sophisticated diagnostic systems that monitor drivetrain components continuously, alerting drivers the moment irregularities are detected.

What Is a Drive Train Malfunction?

A drive train malfunction occurs when your vehicle’s onboard computer system detects anomalies in the components responsible for transferring engine power to the wheels. This complex system includes the transmission, driveshaft, differential, axles, and various sensors that work together to ensure smooth power delivery and optimal vehicle performance.

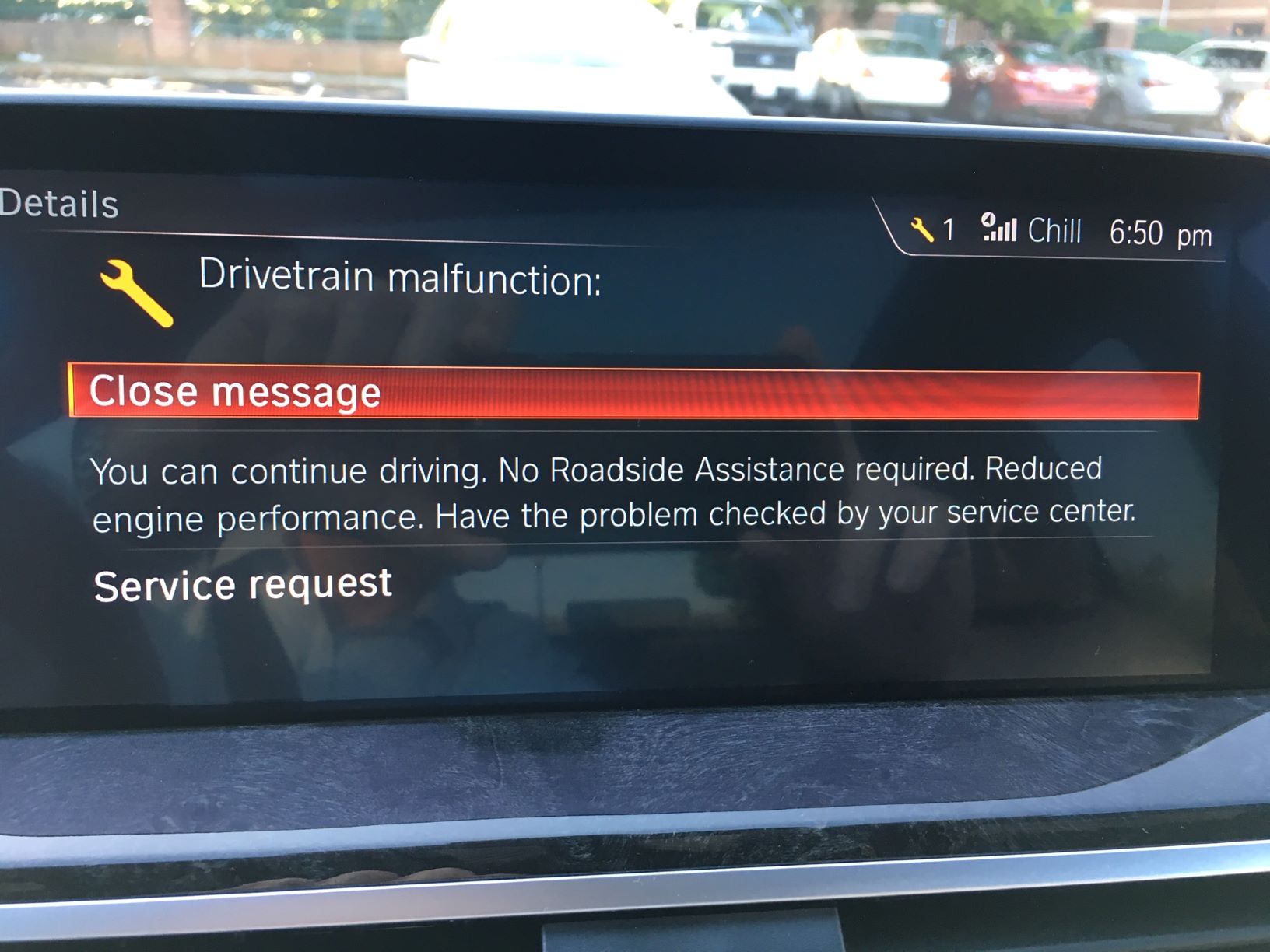

The drivetrain warning typically appears as a message on your dashboard, often accompanied by reduced engine power or performance limitations. Immediate actions, such as turning off the engine for 5-10 minutes and restarting the car, can help reset the computer system and clear the issue, though persistent problems require professional diagnosis.

Modern vehicles use advanced Engine Control Units (ECUs) that continuously monitor drivetrain performance through multiple sensors. These systems can detect everything from transmission fluid temperature fluctuations to unusual vibrations in the driveshaft, triggering the malfunction warning when parameters fall outside normal operating ranges.

Components Involved in Drivetrain Systems

The drivetrain encompasses several interconnected components that must work harmoniously:

- Transmission: Manages gear ratios and power transfer

- Driveshaft: Transmits rotational power from transmission to differential

- Differential: Distributes power between wheels during turns

- Axles: Connect differential to individual wheels

- Universal Joints: Allow driveshaft flexibility during vehicle movement

- CV Joints: Enable wheel movement while maintaining power transfer

Each component contains sensors and monitoring systems that feed data to the vehicle’s computer. When any component operates outside predetermined parameters, the drive train malfunction warning activates to protect the system from further damage.

Common Symptoms of Drive Train Malfunction

Recognizing early warning signs of drivetrain problems can prevent minor issues from escalating into major repairs. Reduced power or performance: A noticeable drop in your vehicle’s power or performance can be a symptom of a drivetrain malfunction. Difficulty accelerating or decelerating: Struggling to accelerate or decelerate smoothly can also indicate a problem with the drivetrain.

Performance-Related Symptoms

Power Loss and Acceleration Issues The most immediate symptom of a drive train malfunction is noticeable power reduction during acceleration. Drivers often report that their vehicle feels sluggish, takes longer to reach highway speeds, or struggles on inclines. This occurs because the vehicle’s computer limits power output to prevent damage to malfunctioning components.

Transmission Problems Shifting issues represent another common symptom category. Automatic transmissions may exhibit delayed engagement, harsh shifting between gears, or complete failure to shift at predetermined points. Manual transmissions might feel sticky, require excessive force to engage gears, or slip out of gear unexpectedly.

Unusual Noises and Vibrations Unusual noises coming from your vehicle can indicate a problem with the drivetrain. Listen for clunking, whining, or grinding sounds when shifting gears or while the vehicle is in motion. These noises may suggest issues with the transmission, differential, or universal joints.

Dashboard Warning Indicators

Modern vehicles provide multiple warning systems for drivetrain issues:

| Warning Type | Description | Urgency Level |

|---|---|---|

| Drive Train Malfunction | Primary warning message | High |

| Transmission Temperature | Overheating alert | Critical |

| Engine Reduced Power | Limited performance mode | Medium |

| Check Engine Light | General system error | Variable |

Physical Symptoms You Can Feel

Steering and Handling Changes Drivetrain malfunctions often manifest through steering wheel vibrations, especially during acceleration or at specific speeds. The vehicle might pull to one side, exhibit unusual handling characteristics, or produce clicking sounds during turns, indicating potential CV joint or differential problems.

Fuel Economy Degradation A malfunctioning drivetrain forces the engine to work harder to maintain performance, resulting in decreased fuel efficiency. Drivers might notice more frequent fill-ups or significantly reduced miles per gallon compared to normal operation.

Primary Causes of Drive Train Malfunction

Understanding the root causes of drive train malfunction helps vehicle owners make informed decisions about maintenance and repairs. The causes of a Drivetrain Malfunction in BMW vehicles can be diverse, reflecting the system’s complexity. Leading causes include: Transmission Issues: Whether your car has a manual or automatic transmission, it can run into issues like leaking fluid, gears wearing out, or sensors not working.

Transmission-Related Failures

Fluid System Problems Transmission fluid serves multiple critical functions: lubrication, cooling, and hydraulic pressure generation. Low fluid levels, contaminated fluid, or incorrect fluid specifications can trigger drivetrain warnings. Regular fluid changes prevent most transmission-related malfunctions, yet many drivers overlook this essential maintenance.

Transmission fluid degradation occurs gradually, with high temperatures, contamination, and normal wear contributing to fluid breakdown. When fluid can no longer perform its functions effectively, internal components experience increased friction, overheating, and premature failure.

Internal Component Wear Transmission internals include numerous moving parts: clutches, bands, gears, and valve bodies. These components experience constant stress and eventually wear beyond acceptable tolerances. The most common causes of a BMW Drivetrain Malfunction are the following: Damaged or worn-out drivetrain components include the transmission, clutch, ignition coils, spark plugs, or differential.

Engine-Related Causes

Ignition System Problems Faulty ignition coils, worn spark plugs, or damaged ignition wiring can create misfires that stress the drivetrain. When cylinders fire inconsistently, the resulting power fluctuations can damage transmission components and trigger malfunction warnings. Regular ignition system maintenance prevents many drivetrain-related issues.

Fuel System Malfunctions Common causes of BMW Drivetrain Malfunction include issues with the engine control unit, damaged fuel injector, clogged catalytic converter, or transmission fuel leak. Fuel delivery problems affect engine performance, which in turn impacts drivetrain operation. Clogged fuel filters, failing fuel pumps, or dirty injectors can all contribute to drivetrain stress.

Sensor and Electronic Failures

Speed Sensor Malfunctions Modern drivetrains rely on multiple speed sensors to monitor wheel rotation, transmission output, and engine speed. When these sensors fail or provide incorrect data, the vehicle’s computer cannot properly manage drivetrain operation, resulting in malfunction warnings and reduced performance.

Control Module Issues The Engine Control Unit (ECU) and Transmission Control Module (TCM) work together to optimize drivetrain performance. Software glitches, electrical problems, or module failures can trigger drive train malfunction warnings even when mechanical components function normally.

Environmental and Usage Factors

Extreme Operating Conditions Severe driving conditions accelerate drivetrain wear and increase malfunction probability. These conditions include:

- Frequent towing of heavy loads

- Stop-and-go traffic patterns

- Extreme temperatures (both hot and cold)

- Mountainous terrain driving

- Poor road conditions and off-road use

Maintenance Neglect Low engine oil level is another cause of the drivetrain malfunction. Skipped maintenance intervals, using incorrect fluids, or ignoring minor symptoms often lead to major drivetrain failures. Regular maintenance following manufacturer specifications prevents most malfunction occurrences.

Diagnostic Procedures for Drive Train Issues

Proper diagnosis is crucial for effective drive train malfunction resolution. Modern diagnostic approaches combine traditional mechanical inspection with advanced electronic testing to identify root causes accurately.

Electronic Diagnostic Testing

OBD-II Scanner Analysis On-Board Diagnostics (OBD-II) systems store fault codes when malfunctions occur. Professional-grade scanners can access manufacturer-specific codes that provide detailed information about the exact nature of drivetrain problems. These codes guide technicians to specific components or systems requiring attention.

Common drivetrain-related fault codes include:

- P0700-P0799: Transmission control system codes

- P1000-P1999: Manufacturer-specific powertrain codes

- P0400-P0499: Emission control system codes affecting drivetrain

- P0100-P0199: Fuel and air metering system codes

Live Data Monitoring Advanced diagnostic equipment can monitor real-time drivetrain parameters while the vehicle operates. This includes transmission temperatures, shift pressures, torque converter operation, and sensor readings. Live data helps identify intermittent problems that might not trigger stored fault codes.

Physical Inspection Methods

Visual Component Assessment Trained technicians perform comprehensive visual inspections of drivetrain components, checking for:

- Fluid leaks around transmission, differential, and axle seals

- Worn or damaged CV joints and boots

- Cracked or deteriorated driveshaft components

- Corroded or loose electrical connections

- Physical damage to transmission case or differential housing

Road Testing Procedures Systematic road testing helps identify performance issues that diagnostic equipment might miss. This includes testing acceleration, deceleration, shifting patterns, and noise levels under various operating conditions. For those interested in performance testing, an epic driver course can provide valuable insights into vehicle dynamics and performance assessment.

Specialized Testing Equipment

Transmission Pressure Testing Hydraulic pressure testing measures transmission fluid pressures during operation, identifying internal wear or valve body problems. Low pressure readings indicate worn pumps, damaged seals, or clogged filters, while excessive pressures might suggest restricted fluid passages or faulty pressure regulators.

Vibration Analysis Sophisticated vibration analysis equipment can identify drivetrain imbalances, worn bearings, or damaged components that create unusual vibrations. This testing is particularly valuable for diagnosing driveshaft, differential, and axle problems.

Repair Solutions and Cost Analysis

Addressing drive train malfunction issues requires understanding both immediate fixes and long-term solutions. Repair approaches vary significantly based on the underlying cause, vehicle age, and component availability.

Immediate Response Strategies

Temporary Reset Procedures When drivetrain malfunction warnings first appear, simple reset procedures might resolve software-related issues. Turning off the engine for 5-10 minutes allows the system to reset and clear temporary faults. However, recurring warnings indicate genuine mechanical problems requiring professional attention.

Safe Driving Protocols If malfunction warnings appear while driving, reduce speed gradually and avoid aggressive acceleration or deceleration. Many vehicles automatically limit power output to protect drivetrain components, making it essential to drive conservatively until proper repairs are completed.

Component-Specific Repair Approaches

Transmission Repairs Transmission repairs range from simple fluid changes to complete rebuilds, depending on the extent of damage:

| Repair Type | Cost Range | Time Required | Effectiveness |

|---|---|---|---|

| Fluid Service | $150-$300 | 1-2 hours | High for early issues |

| Solenoid Replacement | $300-$800 | 2-4 hours | Moderate to high |

| Valve Body Rebuild | $800-$1,500 | 4-8 hours | High |

| Complete Rebuild | $2,500-$5,000 | 3-5 days | Very high |

Engine-Related Repairs When engine problems cause drivetrain stress, addressing ignition, fuel, or emission system issues often resolves malfunction warnings. Common repairs include spark plug replacement, ignition coil replacement, fuel injector cleaning, or catalytic converter replacement.

Preventive Maintenance Strategies

Regular Service Intervals Following manufacturer-recommended maintenance schedules significantly reduces drive train malfunction occurrences. Key maintenance items include:

- Transmission fluid changes every 30,000-60,000 miles

- Differential service every 50,000-75,000 miles

- Engine oil changes at recommended intervals

- Spark plug replacement every 30,000-100,000 miles

- Fuel system cleaning every 30,000 miles

Quality Component Usage Using OEM or high-quality aftermarket parts ensures optimal drivetrain performance and longevity. Cheap replacement parts might provide short-term cost savings but often lead to premature failures and recurring problems.

Advanced Repair Technologies

Adaptive Learning Reset Many modern transmissions use adaptive learning systems that adjust shift points and pressures based on driving patterns. After major repairs, these systems require reset procedures to ensure optimal performance. Failure to perform these resets can result in continued performance issues despite successful mechanical repairs.

Software Updates Manufacturers occasionally release software updates that address known drivetrain issues. These updates can resolve intermittent problems, improve shift quality, or enhance system reliability without requiring physical component replacement.

Prevention and Maintenance Best Practices

Preventing drive train malfunction issues requires consistent attention to maintenance schedules and early recognition of warning signs. Proactive maintenance costs significantly less than major repairs and ensures reliable vehicle operation.

Regular Maintenance Scheduling

Transmission Service Programs Establishing regular transmission service intervals prevents most drivetrain problems. Service includes fluid replacement, filter changes, and system inspections. Modern synthetic transmission fluids last longer than conventional fluids but still require periodic replacement to maintain optimal performance.

Engine Maintenance Integration Drivetrain health depends heavily on engine condition. Regular oil changes, air filter replacement, and fuel system maintenance reduce drivetrain stress and extend component life. Clean engine oil ensures proper lubrication of timing chains, variable valve timing systems, and other components that affect drivetrain operation.

Driving Habit Modifications

Gentle Acceleration and Deceleration Aggressive driving patterns accelerate drivetrain wear and increase malfunction probability. Gradual acceleration reduces stress on transmission components, while engine braking and gentle deceleration extend brake and drivetrain life.

Proper Warm-Up Procedures Allowing sufficient warm-up time before aggressive driving lets transmission fluid reach optimal operating temperature. Cold fluid has different viscosity characteristics and may not provide adequate lubrication during initial operation.

Early Detection Methods

Performance Monitoring Drivers should monitor fuel economy, shift quality, and acceleration performance regularly. Gradual changes often indicate developing problems that can be addressed before major failures occur. Keeping detailed maintenance records helps identify patterns and potential issues.

Sound and Vibration Awareness Unusual noises, vibrations, or performance changes require immediate attention. Early intervention prevents minor issues from escalating into major drive train malfunction situations requiring extensive repairs.

Frequently Asked Questions About Drive Train Malfunction

What does drive train malfunction mean?

A drive train malfunction indicates that your vehicle’s computer has detected a problem with components responsible for transferring power from the engine to the wheels. This includes the transmission, driveshaft, differential, and related systems.

Can I drive with a drive train malfunction warning?

While you may be able to drive short distances with reduced power, continuing to drive with a drive train malfunction warning can cause additional damage. It’s recommended to have the vehicle diagnosed as soon as possible to prevent costly repairs.

How much does it cost to fix a drive train malfunction?

Repair costs vary widely depending on the underlying cause, ranging from $200 for minor sensor replacements to $5,000+ for major transmission rebuilds. Early diagnosis and intervention typically result in lower repair costs.

What causes sudden drive train malfunction?

Sudden drive train malfunction warnings can result from sensor failures, low transmission fluid, overheating, or internal component damage. Electrical issues and software glitches can also trigger unexpected warnings.

How long can you drive with drive train malfunction?

The distance you can safely drive depends on the severity of the problem. Some malfunctions allow limited driving in “limp mode,” while others require immediate attention. Consult a qualified technician for specific guidance.

Will drive train malfunction clear itself?

Minor software-related drive train malfunction warnings might clear after engine restart, but mechanical problems require proper diagnosis and repair. Recurring warnings indicate genuine issues that won’t resolve without intervention.

For more information about drivetrain issues and professional diagnostic services, visit automotive repair specialists who specialize in drive train malfunction diagnosis and repair.

Take Action Now: If you’re experiencing drive train malfunction symptoms, don’t wait for the problem to worsen. Contact a qualified automotive technician today for proper diagnosis and repair solutions that will get your vehicle back to optimal performance.