The needle driver stands as one of the most critical instruments in any surgical toolkit, serving as the bridge between a surgeon’s skill and successful patient outcomes. These precision instruments, also known as needle holders, enable medical professionals to grasp, manipulate, and control surgical needles with the accuracy and stability required for complex suturing procedures. Whether you’re performing delicate microsurgery or robust orthopedic procedures, selecting the right needle driver can significantly impact your surgical efficiency and patient safety.

Modern surgical practices demand instruments that combine durability, precision, and ergonomic design. The evolution of needle driver technology has transformed these tools from simple grasping devices into sophisticated instruments engineered for specific surgical applications. Understanding the nuances of different needle holder designs, materials, and features becomes essential for medical professionals seeking to optimize their surgical performance and achieve superior patient outcomes.

Understanding Needle Driver Fundamentals

What Makes a Quality Needle Driver?

A superior needle driver incorporates several key engineering principles that distinguish professional-grade instruments from basic models. The jaw design represents the most critical component, featuring precisely machined surfaces that provide secure needle grip without causing damage to the needle shaft or compromising its structural integrity. Professional needle holders utilize tungsten carbide inserts within the jaw faces, creating a non-slip surface that maintains consistent grip pressure throughout extended surgical procedures.

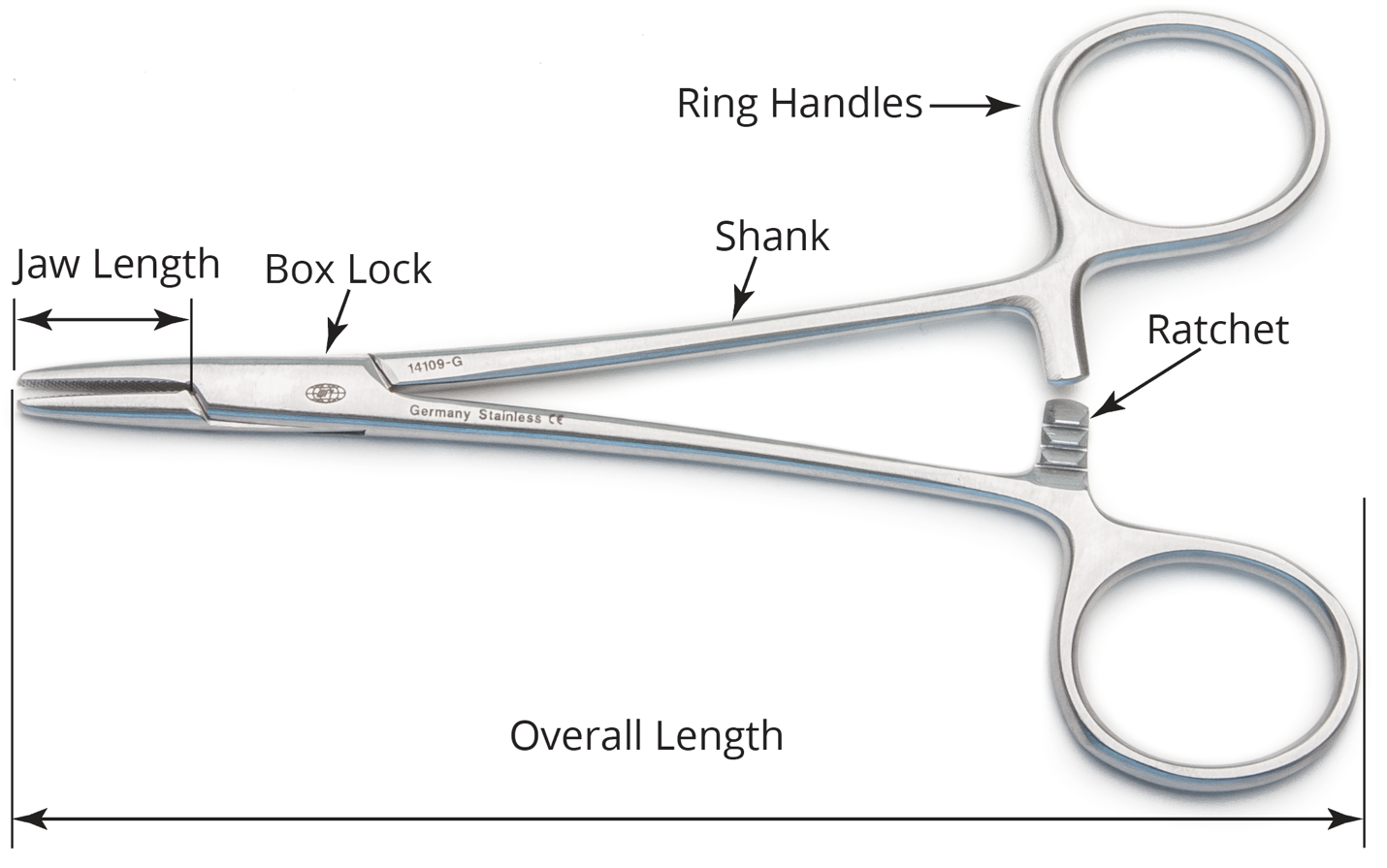

The locking mechanism serves as another fundamental aspect of needle driver design. Quality instruments feature smooth, reliable locking systems that engage securely without requiring excessive force, allowing surgeons to maintain precise control while reducing hand fatigue during lengthy procedures. The ratchet system should provide multiple locking positions to accommodate various needle sizes and suture materials, ensuring optimal grip pressure for each specific application.

Handle ergonomics play a crucial role in surgical comfort and precision. Modern needle driver designs incorporate finger rings sized to accommodate surgical gloves while maintaining comfortable grip angles that reduce wrist strain. The overall balance of the instrument affects control and maneuverability, with properly weighted designs enabling smooth, natural hand movements that translate directly into improved suturing accuracy.

Material Science and Construction Quality

Premium needle driver instruments utilize high-grade stainless steel alloys specifically formulated for surgical applications. These materials provide exceptional corrosion resistance, maintaining their performance characteristics through countless sterilization cycles while resisting the chemical effects of surgical solutions and bodily fluids. The steel composition affects both durability and spring tension, with properly formulated alloys maintaining consistent jaw pressure over extended service life.

Surface treatments enhance the performance and longevity of professional needle holders. Satin finishes reduce glare under surgical lighting while providing improved grip characteristics for wet conditions. Some manufacturers apply specialized coatings that further enhance corrosion resistance and reduce friction between moving parts, resulting in smoother operation and extended instrument life.

Heat treatment processes determine the final mechanical properties of needle driver components. Properly heat-treated instruments maintain their spring tension and jaw alignment through thousands of operating cycles, while inferior processing can result in premature wear, loss of grip pressure, or misalignment that compromises surgical precision.

Types and Classifications of Needle Drivers

Standard Needle Holders

Traditional needle driver designs represent the foundation of surgical suturing instruments, featuring straight or curved configurations suited for general surgical applications. These instruments typically measure between 140mm and 200mm in overall length, providing versatility for various surgical procedures while maintaining comfortable handling characteristics for most surgeons.

Straight needle drivers offer optimal control for surface suturing and procedures requiring direct approach angles. The linear alignment between handle and jaws enables precise needle placement and reduces the learning curve for new surgical personnel. These instruments excel in plastic surgery, dermatological procedures, and general wound closure applications where visibility and access permit direct approach techniques.

Curved needle drivers provide enhanced access for deep surgical sites and confined spaces where straight instruments would prove inadequate. The angled jaw design enables surgeons to approach suturing sites from optimal angles while maintaining clear visualization of the operative field. These instruments prove particularly valuable in cardiovascular, thoracic, and abdominal procedures where anatomical structures limit access.

Specialized Microsurgical Needle Drivers

Microsurgical applications demand needle driver instruments engineered for extreme precision and delicate tissue handling. These specialized tools feature significantly reduced dimensions, with jaw widths often measuring less than 2mm and overall lengths ranging from 100mm to 140mm. The reduced scale enables manipulation of extremely fine sutures while providing the control necessary for procedures involving nerves, blood vessels, and other delicate structures.

Spring-loaded microsurgical needle drivers incorporate tension systems that provide consistent jaw pressure without requiring continuous hand pressure from the surgeon. This design reduces fatigue during extended microsurgical procedures while ensuring consistent needle grip throughout the operation. The spring mechanism must be precisely calibrated to provide adequate holding force without crushing delicate needles or fine suture materials.

Locking microsurgical needle drivers offer traditional ratchet mechanisms scaled for microsurgical applications. These instruments provide secure needle retention during complex manipulations while allowing quick release when necessary. The locking system must operate smoothly with minimal force requirements, as excessive pressure can disrupt the precise hand movements required for microsurgical success.

Cardiovascular and Thoracic Needle Drivers

Cardiovascular surgery presents unique challenges that require specialized needle driver designs optimized for working within confined spaces and around vital structures. These instruments often feature extended lengths ranging from 200mm to 300mm, enabling access to deep surgical sites while maintaining safe distances from critical organs and vessels.

Long needle drivers designed for cardiovascular applications incorporate reinforced construction to prevent flexing under load while maintaining precise jaw alignment across extended instrument lengths. The additional length requires careful balance considerations to prevent tip tremor and maintain surgical precision during delicate suturing procedures.

Angled cardiovascular needle drivers provide specialized jaw orientations designed for specific anatomical approaches common in cardiac and thoracic surgery. These instruments enable optimal suture placement around curved anatomical structures while reducing the need for awkward hand positions that could compromise surgical precision or increase fatigue.

Key Features and Specifications

Jaw Design and Performance Characteristics

The jaw configuration of a needle driver directly impacts its performance across different surgical applications. Serrated jaw patterns provide enhanced grip on smooth needle surfaces, with the depth and spacing of serrations optimized for specific needle types and sizes. Fine serrations work best with delicate needles and small sutures, while coarser patterns suit larger needles and robust suture materials.

Smooth jaw designs eliminate the risk of needle damage while providing adequate grip for most surgical applications. These surfaces rely on precise manufacturing tolerances and proper jaw pressure to maintain needle security without the mechanical advantage provided by serrated patterns. Smooth jaws prove particularly valuable when working with specialized needle coatings or delicate materials that could be damaged by aggressive grip surfaces.

Tungsten carbide inserts represent the premium option for needle driver jaw construction. These extremely hard inserts provide superior grip characteristics while resisting wear from repeated use. The carbide material maintains its surface texture through thousands of operating cycles, ensuring consistent performance throughout the instrument’s service life. Quality carbide inserts feature proper integration with the steel jaw structure to prevent separation or loosening during use.

Locking Mechanisms and Control Systems

Traditional ratchet locking systems in needle driver instruments provide multiple holding positions to accommodate various needle sizes and grip requirements. The ratchet teeth must be precisely machined to ensure smooth engagement and release while providing secure holding power under surgical loads. Quality ratchet systems offer fine adjustment increments that enable optimal grip pressure for each specific application.

Self-retaining needle drivers incorporate spring-loaded mechanisms that automatically maintain grip pressure without requiring continuous hand pressure from the surgeon. These systems reduce fatigue during extended procedures while ensuring consistent needle retention throughout complex suturing sequences. The spring tension must be calibrated to provide adequate holding force while allowing easy needle release when required.

Quick-release mechanisms enable rapid needle changes during fast-paced procedures or when working with multiple suture types. These systems typically feature thumb-activated releases that disengage the locking mechanism instantly while maintaining positive control over needle position. The release mechanism must operate reliably even when contaminated with surgical fluids or blood.

Size and Length Considerations

Needle driver selection must account for the specific requirements of each surgical procedure, with instrument length affecting both access and control characteristics. Short needle drivers (100-140mm) provide maximum precision and control for surface procedures and delicate work, while longer instruments (180-300mm) enable access to deep surgical sites at the expense of some precision.

| Length Range | Applications | Advantages | Considerations |

|---|---|---|---|

| 100-140mm | Microsurgery, plastic surgery, ophthalmology | Maximum precision, reduced fatigue | Limited reach, requires good access |

| 140-180mm | General surgery, gynecology, urology | Versatile, good balance | Moderate reach and precision |

| 180-220mm | Abdominal surgery, orthopedics | Good deep access, sturdy construction | Increased weight, reduced precision |

| 220-300mm | Cardiovascular, thoracic surgery | Maximum reach, specialized applications | Heavy, requires experience |

The jaw width of a needle driver must match the needle sizes commonly used in specific surgical applications. Narrow jaws (1-3mm) suit microsurgical needles and fine sutures, while wider designs (4-8mm) accommodate larger needles used in orthopedic and cardiovascular procedures. Proper jaw width ensures secure needle retention without crushing or damaging the needle structure.

Selection Criteria for Medical Professionals

Procedure-Specific Requirements

Selecting the optimal needle driver requires careful consideration of the specific surgical procedures in your practice. Plastic surgery applications demand instruments with exceptional precision and smooth operation, typically favoring shorter lengths with fine jaw serrations or smooth surfaces that won’t damage delicate needles. The instrument weight should be minimized to reduce fatigue during detailed cosmetic procedures requiring extended suturing times.

Orthopedic surgery presents different requirements, with procedures often involving larger needles and heavy suture materials that demand robust needle driver construction. These applications benefit from longer instruments with substantial jaw width and aggressive serration patterns that provide secure grip on large needles. The overall construction must withstand the higher forces associated with suturing through dense tissue and bone.

Cardiovascular procedures require specialized needle driver designs that combine extended reach with precision control. These instruments must navigate confined spaces around vital structures while maintaining the accuracy necessary for vascular anastomoses and cardiac repairs. The design should minimize bulk while providing stable platform for precise suture placement in critical applications.

Budget and Value Considerations

Professional needle driver instruments represent a significant investment that must be evaluated based on long-term value rather than initial cost alone. Premium instruments from established manufacturers typically offer superior materials, precision manufacturing, and extended service life that justify higher initial costs through reduced replacement frequency and improved surgical outcomes.

Mid-range needle drivers provide acceptable performance for many applications while offering more accessible pricing for practices with budget constraints. These instruments often incorporate quality construction with some compromises in materials or manufacturing precision that may affect longevity but still deliver reliable performance for general surgical applications.

Entry-level options serve specific purposes in training environments or low-volume practices where cost considerations outweigh performance requirements. However, medical professionals should carefully evaluate whether these instruments meet the precision and reliability standards required for their specific surgical applications.

Maintenance and Sterilization Compatibility

Modern needle driver instruments must withstand rigorous sterilization protocols while maintaining their performance characteristics throughout extended service life. Steam sterilization compatibility requires materials and construction methods that resist the corrosive effects of high-temperature steam and chemical indicators used in autoclave processes.

Chemical sterilization presents different challenges, with instruments requiring resistance to glutaraldehyde, hydrogen peroxide, and other sterilizing agents commonly used in healthcare facilities. The instrument surface treatments and joint construction must prevent chemical penetration that could cause corrosion or mechanism failure over time.

Regular maintenance protocols extend needle driver service life while ensuring consistent performance. Proper cleaning removes surgical debris that could interfere with mechanism operation, while periodic lubrication of moving parts prevents wear and ensures smooth operation. Quality instruments should include maintenance guidelines that specify cleaning agents, lubrication requirements, and inspection procedures.

Leading Brands and Manufacturers

Premium Professional Brands

Aesculap has established itself as a leading manufacturer of surgical instruments, including high-quality needle driver options that serve demanding surgical applications worldwide. Their instruments feature precision German engineering with tungsten carbide inserts, ergonomic handle designs, and robust construction that withstands intensive use in busy surgical centers. Aesculap needle holders often incorporate innovative features such as improved locking mechanisms and specialized jaw configurations optimized for specific surgical specialties.

Surgical Holdings produces professional-grade needle driver instruments known for their consistent quality and competitive pricing. Their product line includes standard and specialized designs suitable for various surgical applications, with particular strength in microsurgical instruments and cardiovascular applications. The company’s commitment to quality control ensures reliable performance across their instrument range.

German-manufactured instruments generally represent the premium tier of needle driver quality, with companies like Aesculap, Tuttlingen-based manufacturers, and other European producers offering instruments that combine traditional craftsmanship with modern manufacturing technology. These instruments typically command higher prices but deliver superior performance and extended service life that justifies the investment for demanding applications.

Value-Oriented Options

Pakistani manufacturers have developed significant capabilities in surgical instrument production, offering needle driver options that provide acceptable performance at reduced costs. These instruments often feature quality stainless steel construction with adequate precision for general surgical applications, making them attractive options for practices with budget constraints or high-volume usage patterns.

Chinese manufacturers produce a wide range of needle driver instruments spanning from basic models to sophisticated designs that rival premium brands. The quality varies significantly between manufacturers, requiring careful evaluation of specific products and suppliers to ensure adequate performance and reliability for medical applications.

Domestic manufacturers in various countries provide needle driver options tailored to local market requirements and regulatory standards. These companies often offer advantages in terms of customer service, warranty support, and rapid availability that may offset higher costs compared to imported alternatives.

Emerging Technologies and Innovations

Recent developments in needle driver technology focus on ergonomic improvements and specialized applications that address evolving surgical techniques. Lightweight materials such as titanium alloys provide strength comparable to stainless steel while reducing instrument weight, potentially reducing surgeon fatigue during extended procedures.

Advanced surface treatments enhance the performance characteristics of modern needle driver instruments. Specialized coatings can improve corrosion resistance, reduce friction between moving parts, and provide enhanced grip characteristics under challenging surgical conditions. Some manufacturers incorporate antimicrobial surface treatments that provide additional infection control benefits.

Ergonomic innovations address the occupational health concerns associated with repetitive surgical procedures. Improved handle designs, balanced weight distribution, and reduced operating forces help minimize the risk of repetitive stress injuries while maintaining the precision required for successful surgical outcomes.

Where to Buy Needle Drivers

Authorized Medical Equipment Dealers

Professional medical equipment dealers provide the most reliable source for quality needle driver instruments, offering authentic products backed by manufacturer warranties and technical support. These dealers typically maintain relationships with leading instrument manufacturers and can provide detailed product information, comparison guidance, and after-sale support services that ensure optimal instrument selection and performance.

Regional medical supply companies often provide personalized service and rapid delivery for local healthcare facilities. These companies understand local market requirements and can offer tailored solutions that meet specific practice needs while providing ongoing support for instrument maintenance and replacement needs.

National medical equipment distributors leverage purchasing power to offer competitive pricing on needle driver instruments while maintaining broad product selections from multiple manufacturers. These companies typically provide online ordering systems, detailed product catalogs, and standardized customer service procedures that streamline the purchasing process for busy healthcare facilities.

Online Medical Supply Platforms

Specialized medical e-commerce platforms have revolutionized access to surgical instruments, providing comprehensive product information, competitive pricing, and convenient ordering processes for needle driver purchases. These platforms often feature detailed product specifications, customer reviews, and comparison tools that facilitate informed purchasing decisions.

Manufacturer direct sales programs enable healthcare facilities to purchase needle driver instruments directly from producers, potentially reducing costs while ensuring authentic products and direct technical support. Many manufacturers now offer online ordering systems that provide access to their complete product lines with detailed specifications and pricing information.

Bulk purchasing programs provide significant cost savings for high-volume users of needle driver instruments. These programs typically require minimum order quantities but offer substantial discounts that can significantly reduce per-unit costs for practices that use multiple instruments or require frequent replacements.

Considerations for International Purchases

Regulatory compliance represents a critical consideration when purchasing needle driver instruments from international suppliers. Medical devices must meet local regulatory requirements, including FDA approval in the United States, CE marking in Europe, and equivalent certifications in other jurisdictions. Purchasing from authorized dealers ensures compliance with applicable regulations.

Quality verification becomes particularly important when sourcing needle driver instruments from overseas suppliers. Reputable dealers provide certificates of quality, material certifications, and performance testing documentation that verify instrument specifications and manufacturing standards. This documentation becomes essential for regulatory compliance and quality assurance programs.

Warranty and support services may be limited when purchasing needle driver instruments from distant suppliers. Consider the availability of local service, warranty coverage, and replacement parts when evaluating international purchasing options. The cost savings from overseas purchases may be offset by increased support costs or reduced availability of after-sale services.

Professional Applications and Use Cases

Surgical Specialties and Specific Requirements

Plastic and reconstructive surgery demands needle driver instruments that provide exceptional precision for detailed suturing work. These procedures often involve fine sutures and delicate tissue handling that requires smooth jaw surfaces and precise control. Surgeons typically prefer shorter instruments with reduced weight to minimize fatigue during extended procedures focused on aesthetic outcomes.

Cardiovascular surgery presents unique challenges that require specialized needle driver designs optimized for working around vital structures and within confined spaces. These applications often utilize longer instruments with angled jaws that enable optimal approach angles for vascular anastomoses and cardiac repairs. The instruments must provide secure needle grip while enabling precise suture placement in critical applications.

Neurosurgery requires needle driver instruments engineered for extreme precision when working around delicate neural structures. These applications often favor microsurgical designs with spring-loaded mechanisms that provide consistent grip pressure without requiring continuous hand pressure from the surgeon. The reduced dimensions enable manipulation within confined surgical spaces while maintaining the control necessary for successful outcomes.

Orthopedic surgery involves robust needle driver applications that must handle larger needles and heavy suture materials used for repairs involving bones, joints, and dense connective tissues. These instruments require substantial construction with aggressive jaw serrations that provide secure grip on large needles while withstanding the higher forces associated with orthopedic procedures.

Training and Educational Applications

Medical education programs require needle driver instruments that provide reliable performance while withstanding intensive use by students learning surgical techniques. These applications often benefit from durable construction that maintains consistent performance despite frequent use and occasional mishandling by inexperienced users.

Surgical simulation programs utilize needle driver instruments in realistic training environments that replicate actual surgical conditions. These applications require instruments that provide authentic feel and performance characteristics while withstanding repeated use in training scenarios. The instruments should match the specifications of those used in actual surgical practice to ensure effective skill transfer.

Skills assessment programs depend on standardized needle driver instruments that provide consistent performance characteristics across multiple evaluation sessions. These applications require instruments with proven reliability and consistent specifications that ensure fair and accurate assessment of surgical skills development.

Research and Development Applications

Biomedical research often requires specialized needle driver instruments designed for specific experimental protocols or unique applications not addressed by standard surgical instruments. These applications may involve modified jaw configurations, specialized materials, or custom dimensions that meet specific research requirements.

Instrument testing and evaluation programs utilize needle driver instruments as reference standards for performance comparison and quality assessment. These applications require instruments with documented performance characteristics and consistent specifications that enable accurate testing and evaluation of new designs or materials.

Prototype development activities often involve needle driver instruments as platforms for testing new features, materials, or design concepts. These applications require instruments that can be modified or adapted to evaluate specific design elements while maintaining core functionality for meaningful testing.

Call to Action

Ready to upgrade your surgical instruments with professional-grade needle driver options? Explore our comprehensive selection of premium needle holders designed for demanding surgical applications. Whether you need microsurgical precision instruments or robust needle drivers for cardiovascular procedures, we offer authentic products from leading manufacturers with competitive pricing and reliable support.

Visit our needle driver collection to compare specifications, read detailed reviews, and find the perfect instruments for your surgical practice. Our expert team provides personalized recommendations based on your specific requirements and can assist with bulk ordering for healthcare facilities.

For those seeking to drive for gold in surgical excellence, investing in quality needle driver instruments represents a crucial step toward optimal patient outcomes and professional success.

Frequently Asked Questions About Needle Drivers

What is the difference between a needle driver and needle holder?

Needle driver and needle holder are terms used interchangeably to describe the same surgical instrument. Both terms refer to the specialized forceps designed to grasp and manipulate surgical needles during suturing procedures. The terminology preference often varies by region, specialty, or institutional preference, but the instruments serve identical functions in surgical applications.

How do I choose the right size needle driver for my procedures?

Selecting the appropriate needle driver size depends on several factors including the surgical specialty, procedure location, and needle sizes commonly used. Microsurgical procedures typically require shorter instruments (100-140mm) for maximum precision, while deep abdominal or cardiovascular procedures may need longer options (180-300mm) for adequate reach. Consider the needle sizes you use most frequently and choose jaw widths that accommodate those needles securely.

What maintenance is required for needle driver instruments?

Proper needle driver maintenance includes thorough cleaning after each use to remove surgical debris, followed by appropriate sterilization according to facility protocols. Inspect instruments regularly for jaw alignment, locking mechanism function, and surface condition. Periodic professional servicing may be required to maintain optimal performance, including sharpening or replacement of tungsten carbide inserts when present.

Can needle drivers be resharpened or repaired?

Quality needle driver instruments can often be professionally serviced to restore optimal performance. Tungsten carbide inserts can typically be replaced when worn, and minor adjustments to jaw alignment or locking mechanisms can extend instrument life. However, severely worn or damaged instruments may require replacement to ensure reliable surgical performance and patient safety.

What is the typical lifespan of a professional needle driver?

The service life of a needle driver varies significantly based on usage frequency, maintenance quality, and original manufacturing standards. Premium instruments with proper care can provide reliable service for many years and thousands of procedures, while lower-quality options may require replacement after shorter periods. Regular maintenance and proper handling significantly extend instrument lifespan regardless of initial quality level.

Are there specific needle drivers for left-handed surgeons?

Most needle driver instruments feature symmetrical designs suitable for both left and right-handed surgeons. However, some specialized instruments or ergonomic designs may favor specific hand orientations. Left-handed surgeons should evaluate instrument balance and control characteristics to ensure comfortable operation, and some manufacturers offer specifically designed options for left-handed users when needed.

What sterilization methods are compatible with needle drivers?

Modern needle driver instruments typically support multiple sterilization methods including steam autoclaving, chemical sterilization, and gamma irradiation. Always verify sterilization compatibility with specific instruments, as some specialized materials or designs may have limitations. Follow manufacturer guidelines and institutional protocols to ensure proper sterilization without damaging instrument performance or longevity.