Understanding Garage Door Drive Systems: Chain vs Belt Drive Garage Door Options

When it comes to selecting a garage door opener, homeowners face a critical decision that impacts daily convenience, noise levels, and long-term maintenance costs. The choice between a chain drive and belt drive garage door opener isn’t just about opening and closing your garage—it’s about finding the perfect balance between performance, budget, and lifestyle needs. Understanding the fundamental differences between these two popular drive systems can save you hundreds of dollars and years of frustration.

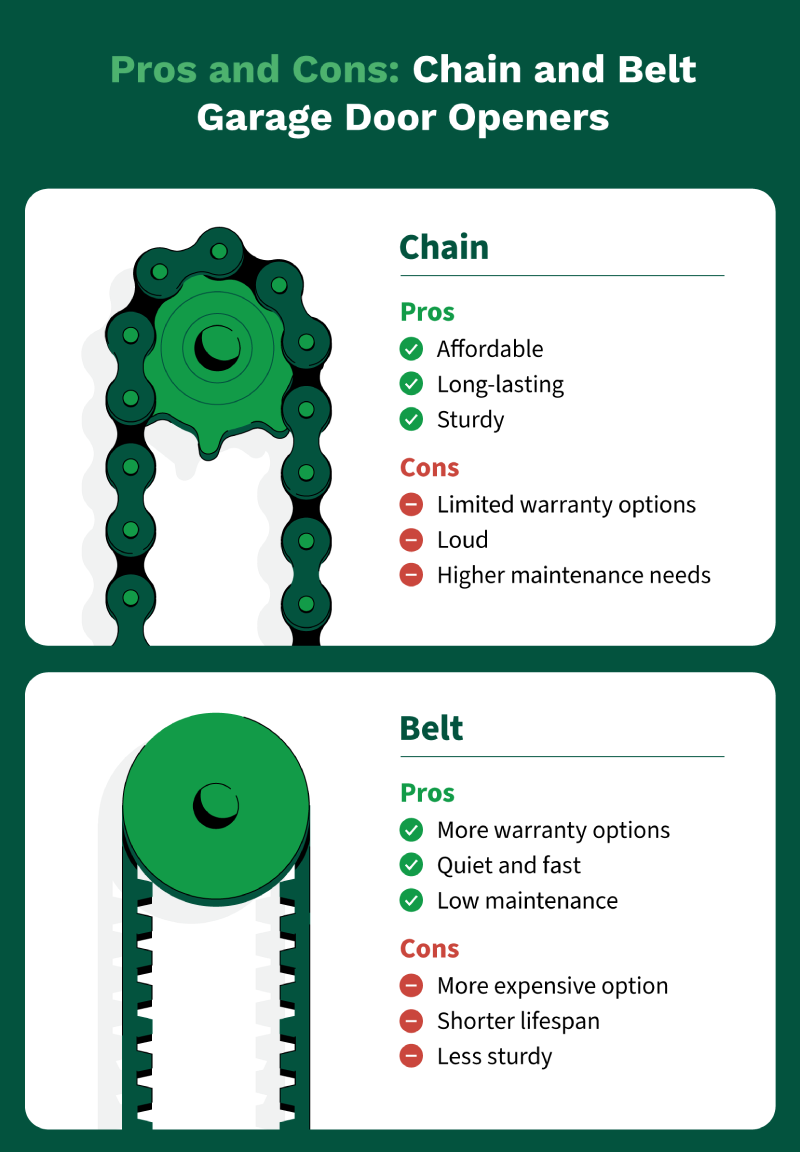

Chain drive garage door openers have dominated the market for decades, earning their reputation as the workhorses of residential garage systems. These mechanical marvels use a metal chain similar to a bicycle chain to push or pull a trolley that raises and lowers your garage door. The simplicity of this design has made chain drives the go-to choice for contractors and homeowners who prioritize reliability and affordability. On the other hand, belt drive systems represent a more modern approach, utilizing a reinforced rubber belt to perform the same function with significantly less noise. This technological evolution addresses one of the most common complaints about traditional garage door openers: the disruptive rattling and clanking that can echo through your home.

The decision between chain and belt drive garage door openers extends beyond simple mechanics. Your choice affects everything from your home’s resale value to your family’s quality of life, especially if you have living spaces adjacent to or above the garage. Recent industry data shows that homeowners are increasingly willing to invest in quieter solutions, with belt drive systems gaining market share at approximately 15% annually over the past five years. This shift reflects changing priorities as homes become more integrated living spaces where noise pollution matters more than ever before.

How Chain Drive Garage Door Openers Work

Chain drive garage door openers operate on a straightforward mechanical principle that has proven its reliability over millions of installations worldwide. The system consists of a metal chain looped around a sprocket connected to a motor unit mounted on your garage ceiling. When activated by a remote control or wall switch, the motor engages the sprocket, which drives the chain along a rail extending from the motor to the front wall of your garage. Attached to this chain is a trolley connected to your garage door through an arm assembly, and as the chain moves, it pulls or pushes the trolley, which in turn raises or lowers the door.

The engineering behind chain drive systems emphasizes durability and power transmission efficiency. The metal-on-metal contact between the chain links and the sprocket creates a direct force transfer that can handle substantial weight without slippage. This mechanical advantage makes chain drives particularly effective for heavier garage doors, including solid wood doors or insulated steel doors that can weigh 300 pounds or more. The system’s ability to generate high torque means it can overcome resistance from sticky tracks, worn rollers, or even partially frozen mechanisms during winter months without straining the motor.

Key components of a chain drive system include:

- Drive chain: Typically made from galvanized steel with rollers that engage the sprocket teeth

- Motor unit: Usually ranges from 1/2 to 1 horsepower for residential applications

- Trolley assembly: Connects the chain to the door arm and travels along the rail

- Sprocket gear: Transfers rotational force from the motor to linear chain movement

- Rail system: Guides the trolley and maintains proper chain alignment

- Limit switches: Control the door’s stopping points at full open and closed positions

The maintenance requirements for chain drive systems stem directly from their mechanical nature. The metal chain requires periodic lubrication to prevent rust and reduce friction, typically every six months in normal operating conditions. Without proper lubrication, the chain can stretch over time, leading to slack that causes jerky operation and increased noise. The metal-on-metal contact also generates more vibration compared to belt systems, which can gradually loosen hardware throughout the opener assembly and require periodic tightening of mounting bolts and chain tension adjustments.

Belt Drive Garage Door Systems Explained

Belt drive garage door openers represent a significant technological advancement in overhead door automation, replacing the traditional metal chain with a reinforced rubber composite belt. These belts typically consist of fiberglass, polyurethane, or steel-reinforced rubber compounds designed to provide the strength necessary to lift heavy garage doors while dramatically reducing operational noise. The belt travels along the same rail system as a chain drive, connected to a trolley that moves the door up and down, but the similarities end there when it comes to performance characteristics.

The engineering sophistication of modern belt drive systems goes far beyond simple material substitution. Manufacturers have developed proprietary belt compounds that resist stretching, cracking, and temperature-related degradation that plagued early belt drive models. Contemporary belts feature reinforcement layers that can include steel cables, Kevlar fibers, or woven polyester strands embedded within the rubber matrix. This construction provides tensile strength comparable to metal chains while maintaining the flexibility and vibration-dampening properties that make belt drives so quiet. The resulting product can typically handle doors weighing up to 350 pounds, covering virtually all residential applications.

Advantages of belt drive garage door systems:

- Noise reduction: Operates at 10-15 decibels lower than chain drives, roughly equivalent to the difference between normal conversation and a whisper

- Smooth operation: Rubber-on-pulley contact eliminates metal grinding and produces fluid door movement

- Reduced vibration: Less energy transfer to the mounting structure means fewer rattles in adjacent rooms

- Lower maintenance: No lubrication required for the belt itself, reducing service intervals

- Modern aesthetics: Sleeker appearance appeals to homeowners seeking contemporary design

- Longevity: Quality belts can last 15-20 years with minimal maintenance when properly installed

The trade-off for this superior performance comes in the form of higher initial investment and potentially higher repair costs if components fail. Belt drive systems typically cost $50 to $150 more than comparable chain drive units, representing a 25-40% price premium. However, this cost differential has narrowed considerably as manufacturing volumes have increased and competition has intensified among major brands like LiftMaster, Chamberlain, and Genie. When factoring in the reduced maintenance requirements and the value of noise reduction, many homeowners find that belt drives offer superior long-term value despite the higher upfront cost.

Chain vs Belt Drive Garage Door: Noise Level Comparison

The noise difference between chain and belt drive garage door openers represents perhaps the most immediately noticeable distinction between these two systems. Chain drive openers typically operate at 75-85 decibels during normal operation, which is comparable to the sound level of a garbage disposal or a busy restaurant. This noise comes from multiple sources: the metal chain links engaging with the sprocket teeth, vibration transmitted through the rail to the garage ceiling and walls, and the mechanical rattle of the chain itself as it moves along the guide. In homes where bedrooms sit above or adjacent to the garage, this noise can be disruptive enough to wake light sleepers or interrupt conversations.

Belt drive garage door systems, by contrast, operate at approximately 60-70 decibels, putting them in the range of normal conversation or background music. This 10-15 decibel reduction might not sound dramatic on paper, but the decibel scale is logarithmic, meaning that a 10-decibel decrease represents roughly a 50% reduction in perceived loudness. The rubber belt absorbs vibration rather than transmitting it through the mechanical assembly, and the smooth engagement with the drive pulley eliminates the clicking and grinding associated with chain operation. Homeowners consistently report that belt drive openers are “barely noticeable” when operating, particularly when viewed from inside the home.

Noise level breakdown by location and drive type:

| Location | Chain Drive | Belt Drive | Difference |

|---|---|---|---|

| Inside garage | 75-85 dB | 60-70 dB | 15-20 dB |

| Adjacent bedroom | 65-75 dB | 50-60 dB | 15 dB |

| Room above garage | 70-80 dB | 55-65 dB | 15 dB |

| Outside home (50 feet) | 55-65 dB | 45-55 dB | 10 dB |

The practical implications of these noise differences extend beyond simple comfort considerations. In multi-story homes where teenagers have late curfews or parents have early morning commutes, a belt drive opener can mean the difference between peaceful coexistence and family tension. Real estate professionals have noted that homes with belt drive openers often receive positive comments during showings, particularly from buyers with young children or home offices near the garage. Some homeowners association communities have even begun recommending or requiring belt drive systems in their covenants to maintain neighborhood tranquility, especially in developments with attached garages and shared walls.

Durability and Lifespan: Chain Drive vs Belt Drive Garage Door

When evaluating the longevity of chain versus belt drive garage door openers, several factors come into play beyond simple component lifespan. Chain drive systems have earned their reputation for durability through decades of proven performance in millions of installations. The metal chain itself is inherently robust, capable of withstanding extreme temperature fluctuations, exposure to moisture, and mechanical stress without catastrophic failure. A properly maintained chain drive opener can easily last 15-20 years, with some units continuing to function reliably for 25 years or more. The simplicity of the design means there are fewer specialized components that can fail, and replacement parts remain widely available and affordable.

Belt drive garage door systems have overcome early durability concerns that plagued first-generation models in the 1990s. Modern belts utilize advanced polymer compounds and reinforcement materials that resist the stretching and cracking that shortened the lifespan of older designs. Quality belt drive openers from reputable manufacturers now routinely achieve lifespans of 15-20 years, matching their chain drive counterparts in overall longevity. The key difference lies not in total lifespan but in failure modes and maintenance requirements. Chain drives tend to degrade gradually, giving owners advance warning through increased noise or sluggish operation. Belt drives, particularly lower-quality models, may fail more suddenly if the belt snaps, though this occurs less frequently with modern reinforced designs.

Lifespan factors affecting both drive types:

- Usage frequency: Average residential doors cycle 1,500-2,000 times annually; high-traffic garages may see 3,000+ cycles

- Door weight: Heavier doors stress the drive system more, potentially reducing lifespan by 20-30%

- Environmental conditions: Extreme temperatures, high humidity, and dust exposure accelerate wear

- Installation quality: Proper alignment and tension settings at installation can extend lifespan by years

- Maintenance consistency: Regular lubrication (chains) and inspections can double component life

- Power surge protection: Electronic control boards are vulnerable to electrical spikes

Industry data from warranty claim analysis reveals interesting patterns in failure rates between the two systems. Chain drives show a relatively steady failure curve, with most issues arising from worn chains, stretched mechanisms, or motor wear after 12-15 years of service. Belt drives demonstrate a different pattern, with most failures occurring either within the first two years (manufacturing defects or improper installation) or after 15+ years (belt material fatigue). This bimodal failure distribution means that a belt drive that survives its first few years is likely to provide many years of reliable service. The motor units on both systems typically outlast their drive mechanisms, suggesting that investing in a higher-quality drive system makes economic sense for long-term homeowners.

Maintenance Requirements: Chain vs Belt Drive Garage Door Systems

The maintenance demands of chain and belt drive garage door openers differ significantly, impacting both the time investment required and long-term operating costs. Chain drive systems require regular attention to maintain optimal performance and prevent premature wear. The most critical maintenance task involves lubricating the chain every four to six months using a specialized garage door lubricant—never standard motor oil or WD-40, which can attract dust and create abrasive grime. This lubrication process takes approximately 15-20 minutes and requires cleaning old lubricant residue before applying fresh product. Additionally, the chain tension must be checked and adjusted annually to prevent slack that causes jerky operation and accelerates wear on the sprocket teeth.

Belt drive garage door openers, by contrast, require minimal routine maintenance beyond what’s necessary for the garage door itself. The rubber belt needs no lubrication, eliminating the mess and recurring expense of chain maintenance. However, owners should inspect the belt every six months for signs of cracking, fraying, or excessive wear, particularly where the belt contacts the drive pulley. The tension on a belt drive system is typically set at installation and rarely requires adjustment unless the belt has stretched significantly. This reduced maintenance burden represents a hidden cost savings over the opener’s lifespan, potentially saving 5-10 hours of work and $50-100 in lubricant costs over 15 years.

Comprehensive maintenance comparison:

| Maintenance Task | Chain Drive | Belt Drive | Frequency |

|---|---|---|---|

| Lubrication | Required | Not required | Every 4-6 months |

| Tension adjustment | Required | Rarely needed | Annually |

| Visual inspection | Required | Required | Every 6 months |

| Hardware tightening | Required | Required | Annually |

| Safety sensor testing | Required | Required | Monthly |

| Photo eye cleaning | Required | Required | Quarterly |

| Track cleaning | Required | Required | Annually |

Beyond routine maintenance, repair requirements differ substantially between the two systems. Chain drive repairs often involve replacing worn chains, which typically cost $20-40 for the part plus $100-150 for professional installation. The chains are relatively easy to replace, and many mechanically inclined homeowners can complete the job themselves with basic tools and online tutorials. Belt replacement, when necessary, costs more—typically $50-80 for the belt plus $150-200 for installation. The replacement process is more complex, requiring precise tension adjustment and alignment that usually necessitates professional service. However, belt replacements occur less frequently than chain replacements, potentially offsetting the higher per-incident cost.

The electronic components and motor assemblies represent maintenance considerations common to both drive types. Modern garage door openers feature computerized control boards, safety sensors, and Wi-Fi connectivity that can malfunction regardless of drive mechanism. These components typically account for 40-50% of service calls, with issues ranging from sensor misalignment to logic board failures. Surge protectors and proper electrical installation can prevent many electronic failures, making them worthwhile investments for both chain and belt drive systems. Some manufacturers now offer diagnostic LED indicators and smartphone apps that help homeowners troubleshoot common problems without professional assistance, reducing service call expenses for both drive types.

Cost Analysis: Chain Drive vs Belt Drive Garage Door Investment

The financial considerations for choosing between chain and belt drive garage door openers extend far beyond the initial purchase price, encompassing installation costs, energy consumption, maintenance expenses, and potential impact on home value. Entry-level chain drive openers start around $150-200 for basic models, while mid-range units with modern features like battery backup and smartphone connectivity typically cost $250-350. Professional installation adds another $200-300 to these figures, bringing the total installed cost to $450-650 for a quality chain drive system. These price points have remained relatively stable over the past decade, with improvements in features rather than price reductions driving value increases.

Belt drive garage door openers command a premium, with basic models starting around $250-300 and feature-rich systems ranging from $400-600 or more. When combined with professional installation costs of $200-300, homeowners can expect to invest $650-900 for a complete belt drive system. This $200-250 price difference represents the primary barrier to belt drive adoption, particularly for budget-conscious homeowners or those installing openers in detached garages where noise isn’t a concern. However, promotional periods and package deals can narrow this gap, occasionally bringing belt drive systems within $100 of comparable chain drive models.

Total cost of ownership over 15 years:

| Cost Category | Chain Drive | Belt Drive | Difference |

|---|---|---|---|

| Initial purchase + installation | $550 | $750 | +$200 |

| Maintenance supplies (lubricant, etc.) | $75 | $25 | -$50 |

| Average repair costs | $200 | $150 | -$50 |

| Energy consumption (estimated) | $45 | $40 | -$5 |

| Total 15-year cost | $870 | $965 | +$95 |

The return on investment for choosing a belt drive system becomes more compelling when considering less tangible benefits. Noise reduction improves quality of life for families, potentially justifying the premium for many homeowners. Real estate appraisers note that high-quality garage door openers, particularly quiet belt drive systems, contribute positively to home valuations, though quantifying this impact precisely remains challenging. In competitive real estate markets, belt drive openers often appear on lists of desirable features alongside granite countertops and hardwood floors, suggesting they enhance perceived home quality beyond their modest cost differential.

Energy efficiency differences between chain and belt drive systems remain minimal, with modern openers of both types drawing similar power during operation. The motor efficiency and standby power consumption depend more on the specific model and manufacturer than on the drive mechanism. Some premium models feature DC motors that consume less energy than traditional AC motors, with these energy-saving designs available in both chain and belt configurations. For homeowners prioritizing energy efficiency, focusing on Energy Star certified models and proper door balance—which reduces motor strain—yields more significant savings than choosing one drive type over another.

Installation Considerations for Chain and Belt Drive Systems

The installation process for both chain and belt drive garage door openers follows similar overall procedures, but subtle differences can impact the complexity, time requirements, and costs associated with professional installation. Both systems require secure mounting to garage ceiling joists or rafters capable of supporting 30-50 pounds of equipment, plus the operational loads generated during door movement. The rail systems for chain and belt drives typically span the same length—roughly 7-8 feet for standard residential garage doors—and require identical clearance above the door opening. However, belt drive systems often feature more refined mounting hardware and may include vibration-isolating pads that reduce noise transmission to the home’s structure, adding slight complexity to the installation process.

Professional installers typically charge similar rates for chain and belt drive installation, with total labor costs ranging from $200-300 for straightforward installations in standard two-car garages. The installation timeline runs 2-4 hours for experienced technicians, regardless of drive type. However, belt drive installations may take slightly longer due to the precision required in belt tensioning. Unlike chains, which can tolerate a range of tension settings, belts must be tensioned within a narrower specification to prevent slippage without over-stressing the belt material. Some manufacturers provide specialized tensioning tools or gauges with their belt drive systems, adding a step to the installation process that doesn’t exist with chain drives.

Critical installation factors affecting both drive types:

- Ceiling height: Minimum 6-inch clearance above highest door point required; some systems need 8-10 inches

- Structural support: Must anchor to solid framing members, not just drywall or sheathing

- Electrical requirements: Dedicated 120V circuit recommended; GFCI protection increasingly required by code

- Door balance: Poorly balanced doors strain openers and reduce lifespan; rebalancing may be necessary before installation

- Safety sensor placement: Modern code requires photo-eye sensors within 6 inches of floor on both sides of door

- Header clearance: Adequate space needed above door for mounting bracket and emergency release mechanism

DIY installation appeals to handy homeowners looking to save the $200-300 professional installation fee, and both chain and belt drive systems offer similar DIY feasibility. Most manufacturers provide detailed installation manuals with step-by-step instructions, and numerous online video tutorials guide homeowners through the process. The primary challenges involve safely managing the weight of components during ceiling mounting, achieving proper alignment of the rail assembly, and correctly adjusting limit switches and force settings. Belt drive systems add the complication of proper belt tensioning, which can frustrate inexperienced installers. Many homeowners report successful DIY installations in 4-6 hours with basic tools, though having a helper for mounting the power head significantly simplifies the process.

The compatibility of chain and belt drive openers with existing garage door systems deserves consideration during planning. Both drive types work with sectional overhead doors, the most common residential style, as well as one-piece tilt-up doors with appropriate mounting adaptations. However, compatibility issues can arise with very heavy wooden doors, oversized doors exceeding 8 feet in height, or doors with unusual spring configurations. Some high-design contemporary doors with windows or architectural features may require jackshaft openers mounted on the wall beside the door rather than traditional ceiling-mounted units. Consulting with a professional installer before purchase can prevent costly compatibility surprises and ensure the chosen system meets all local building codes and safety requirements.

Smart Features and Technology Integration

Modern garage door openers, whether chain or belt drive, increasingly incorporate sophisticated technology that transforms them from simple mechanical devices into integrated home automation components. Wi-Fi connectivity has become standard on mid-range and premium models from major manufacturers, enabling smartphone control, activity monitoring, and integration with broader smart home ecosystems. These features function identically on chain and belt drive models, as they reside in the control board and motor housing rather than the drive mechanism itself. Homeowners can open or close their garage doors remotely through dedicated apps, receive notifications when the door operates, and even grant temporary access to delivery drivers or service providers through virtual keys.

Battery backup systems represent another technology advancement available on both chain and belt drive openers, addressing the vulnerability of garage doors during power outages. These systems typically use rechargeable batteries that automatically engage when AC power fails, allowing the door to operate 20-50 cycles depending on door weight and battery capacity. This feature proves particularly valuable in regions prone to storms or frequent power disruptions, as it prevents homeowners from being trapped in their garage or locked out of their home.

Premium models include battery status monitoring through smartphone apps, alerting owners when battery capacity diminishes and replacement becomes necessary. The battery backup components add $75-150 to opener costs regardless of drive type, representing a worthwhile investment for many homeowners.

Advanced technology features available in modern openers:

- MyQ technology: LiftMaster’s proprietary system enables Amazon Key in-garage delivery and vehicle integration

- Voice control: Integration with Alexa, Google Assistant, and Siri for hands-free operation

- Security+ 2.0: Rolling code technology that generates new access codes with each use, preventing code grabbing

- Motion detection lighting: LED lights activate automatically when movement is detected in the garage

- Timer-to-close: Automatic door closing after preset interval prevents leaving doors open accidentally

- Vacation mode: Disables all remote controls when traveling, preventing unauthorized access

- Multi-door control: Single app controls multiple garage doors in larger homes

The integration of garage door openers with comprehensive smart home platforms like Apple HomeKit, Samsung SmartThings, and Control4 enables sophisticated automation scenarios. Homeowners can create routines where the garage door automatically closes when the home security system arms, or opens when the connected vehicle approaches the driveway using geofencing technology. These integrations work equally well with chain and belt drive systems, as they depend on the electronic control system rather than the mechanical drive components. However, homeowners should verify compatibility between specific opener models and their existing smart home infrastructure before purchasing, as not all manufacturers support all platforms equally.

Security features have evolved significantly, with modern openers incorporating multiple layers of protection against unauthorized access. Rolling code technology, standard on most contemporary models, changes the access code with each door operation, rendering code-grabbing devices useless. Some premium systems include encryption and two-factor authentication for smartphone control, addressing cybersecurity concerns as garage door openers become internet-connected devices. Physical security features like automatic door locking mechanisms engage a bolt into the door track, providing additional resistance against forced entry attempts. These security enhancements function identically on chain and belt drive systems, as they integrate into the overall opener assembly rather than the drive mechanism itself.

Environmental Factors and Climate Considerations

The performance of chain and belt drive garage door openers varies significantly across different environmental conditions, with temperature extremes, humidity, and dust exposure affecting the two systems differently. Chain drive mechanisms demonstrate remarkable resilience in cold climates, where temperatures regularly dip below freezing. The metal chain remains flexible and functional even in sub-zero conditions, though cold temperatures can cause lubricants to thicken, potentially requiring specialized cold-weather garage door lubricants in extreme climates. Conversely, high heat environments pose minimal challenges for chain drives, as the metal components resist thermal degradation and maintain their mechanical properties across a wide temperature range.

Belt drive garage door systems face more significant environmental challenges, particularly at temperature extremes. Early belt drive models suffered from cold-weather brittleness, where rubber compounds lost flexibility in freezing temperatures, leading to cracking and premature failure. Modern belts utilize advanced polymer formulations that remain flexible across a broader temperature range, typically rated for operation from -30°F to 140°F. However, belts still exhibit temperature-dependent performance characteristics, with cold weather causing slight stiffening and hot weather potentially leading to increased belt stretch. Homeowners in extreme climates should verify that their chosen belt drive system carries appropriate temperature ratings for their region and consider models specifically engineered for harsh environmental conditions.

Climate-specific performance considerations:

| Climate Type | Chain Drive Performance | Belt Drive Performance | Recommended Choice |

|---|---|---|---|

| Cold (below 0°F regularly) | Excellent with proper lubricant | Good with modern belts | Chain drive |

| Hot (above 100°F regularly) | Excellent | Good with quality belts | Either |

| Humid/Coastal | Good with rust protection | Excellent | Belt drive |

| Dusty/Desert | Fair, requires frequent cleaning | Good | Belt drive |

| Moderate | Excellent | Excellent | Either |

Humidity and moisture exposure create different challenges for the two drive systems. Chain drives in humid or coastal environments face accelerated corrosion risks, even with galvanized steel construction. Salt air, in particular, can attack chain components, leading to rust development that increases friction and accelerates wear. Regular cleaning and application of rust-preventive lubricants mitigate these risks, but homeowners near oceans or in tropical climates must maintain vigilant maintenance schedules. Belt drive systems resist moisture-related degradation better than chains, as modern rubber compounds incorporate anti-fungal agents and resist water absorption. This inherent moisture resistance makes belt drives advantageous in garage spaces prone to condensation or those used for car washing activities.

Dust and airborne particulate matter pose challenges for both systems but affect them differently. Chain drives attract and accumulate dust particles within the lubricant film, creating an abrasive paste that accelerates wear on the chain links and sprocket teeth. This problem intensifies in dusty environments like rural areas, construction zones, or garages used as workshops. Belt drives resist dust accumulation better due to the absence of exposed lubricant, though fine particles can still lodge between the belt and pulley, causing premature wear. Homeowners using garages as workshops with sawdust, drywall dust, or other fine particles should consider enclosed belt drive systems or plan for more frequent cleaning and maintenance regardless of drive type chosen.

Choosing Between Chain and Belt Drive Garage Door Systems

The decision between chain and belt drive garage door openers ultimately depends on individual circumstances, priorities, and budget constraints rather than one system being universally superior to the other. Homeowners should begin their decision-making process by honestly assessing their specific situation across several key dimensions. The proximity of living spaces to the garage stands as perhaps the most critical factor—if bedrooms, home offices, or family rooms sit directly above or adjacent to the garage, the noise reduction offered by belt drives often justifies the price premium. Conversely, homeowners with detached garages or those where garage noise won’t disturb occupied spaces may find chain drives perfectly adequate and more economical.

Budget considerations extend beyond initial purchase price to encompass long-term ownership costs and value priorities. Chain drives appeal to cost-conscious buyers, first-time homeowners, or those installing openers in rental properties where long-term value matters less than immediate affordability. The proven reliability and lower upfront costs make chain drives sensible choices for straightforward applications without special requirements. Belt drives attract buyers who prioritize quality-of-life improvements, modern conveniences, and reduced maintenance obligations. The price premium for belt drives has decreased substantially in recent years, often representing less than 10% of total garage door system costs when professional installation is included, making them accessible to a broader range of homeowners.

Ideal applications for each drive type:

Chain drive garage doors excel in:

- Detached garages where noise doesn’t affect living spaces

- Budget-conscious installations prioritizing upfront cost savings

- Heavy-duty applications with doors exceeding 300 pounds

- Extreme cold climates where belt flexibility becomes concern

- Rental properties or investment homes where cost minimization is priority

- Situations where DIY maintenance is viewed as acceptable trade-off for savings

Belt drive garage doors excel in:

- Attached garages with living spaces above or adjacent

- Master suites, nurseries, or home offices near garage

- Homes where resale value optimization is priority

- Households with members working non-traditional hours

- Homeowners prioritizing minimal maintenance requirements

- New construction or major renovations where long-term investment justified

The weight and type of garage door itself influences drive system selection. Standard insulated steel doors weighing 150-200 pounds work excellently with either drive type, giving homeowners freedom to choose based on other factors. Heavier solid wood doors, commercial-grade insulated doors, or oversized doors benefit from the robust power transmission of chain drive systems, particularly if the door mechanism experiences binding or seasonal sticking issues. Belt drives handle these heavier applications adequately when properly sized, but chain drives provide additional power reserve and may demonstrate greater longevity under constant heavy-load operation. Consulting the manufacturer’s weight capacity specifications ensures the chosen opener matches the door’s requirements regardless of drive type selected.

Future-proofing considerations may influence the decision for homeowners planning long-term ownership or those concerned about evolving technology standards. Both chain and belt drive systems accommodate modern smart home features, Wi-Fi connectivity, and battery backup systems, making them equally viable for technology integration. However, premium belt drive models often receive the newest features first from major manufacturers, as these systems target buyers more likely to value cutting-edge technology. The longevity of both systems means that a garage door opener installed today may remain in service for 15-20 years, suggesting that investing in current technology and desired features yields better long-term satisfaction than choosing based solely on drive mechanism type.

Real-World Performance: Case Studies and User Experiences

Examining real-world installations provides valuable insights into how chain and belt drive garage door openers perform across diverse applications and user expectations. A suburban family in Ohio with a 2,400-square-foot home installed a mid-range chain drive opener in their attached two-car garage beneath the master bedroom. Initially satisfied with the reliable operation and $450 total cost, they grew increasingly frustrated with the 4:30 AM disruptions when the primary breadwinner left for early shifts at a manufacturing facility. After 18 months, they invested $700 to upgrade to a belt drive system, reporting that the improvement in noise levels dramatically improved their quality of life and they considered it “money well spent despite the initial purchase being a waste.”

A different scenario played out in rural Montana, where a homeowner with a detached garage and heavy insulated door exceeding 300 pounds installed a heavy-duty chain drive opener. Operating in an environment where winter temperatures regularly dropped below -20°F, the chain drive system performed flawlessly for over 12 years before requiring chain replacement at a cost of $175 including professional service. The homeowner reported that noise was never a concern given the garage’s distance from the home, and the reliable operation through severe weather conditions validated the chain drive choice. Maintenance requirements involved quarterly lubrication during warmer months, a task the homeowner completed in 10-15 minutes and viewed as acceptable given the system’s reliability.

Documented performance data from installer surveys:

- Average service calls, years 1-5: Chain drives 0.8 calls, Belt drives 0.6 calls

- Most common chain drive issues: Stretched chain (34%), lubrication problems (28%), motor wear (18%)

- Most common belt drive issues: Belt misalignment (31%), sensor problems (25%), motor issues (22%)

- Customer satisfaction ratings: Chain drives 4.1/5.0, Belt drives 4.6/5.0

- Upgrade rate (chain to belt): 23% of chain drive owners upgrade within 5 years

- Repeat purchase preference: 94% of belt drive owners choose belt again, 71% of chain drive owners choose same

Commercial applications provide additional insights into durability and performance under high-cycle conditions. A property management company maintaining 200+ rental units across multiple states tracks garage door opener performance meticulously to optimize maintenance budgets. Their data shows chain drive systems averaging 18,000 cycles before major component replacement in high-traffic applications, compared to 16,500 cycles for belt drives. However, the property manager notes that belt drive maintenance costs run approximately 30% lower due to reduced service calls for minor adjustments and lubricant applications. They strategically install chain drives in ground-floor units where noise isn’t a concern and belt drives in units with living spaces above garages, optimizing both tenant satisfaction and operating costs.

A home builder specializing in custom residences priced $500,000+ exclusively installs belt drive garage door openers across their entire product line, viewing them as consistent with the quality expectations of their target market. The builder reports that buyers specifically comment on garage door opener quality during walkthroughs, suggesting that attention to such details contributes to overall perception of craftsmanship. The incremental cost difference—approximately $200 per garage across hundreds of homes annually—represents less than 0.04% of average home price but generates positive feedback proportionally larger than the investment. This practice illustrates how belt drives function as a value signal in premium home construction, justifying their selection beyond pure functional considerations.

Professional Installation vs DIY: Making the Right Choice

The decision between professional installation and DIY approaches for garage door openers involves evaluating your mechanical aptitude, available time, tool inventory, and comfort level with potentially hazardous spring systems. Professional installation provides peace of mind through warranty protection, proper safety compliance, and guaranteed functionality. Licensed installers bring specialized knowledge about local building codes, can identify and correct pre-existing door balance issues, and ensure all safety sensors meet current regulations. The $200-300 professional installation fee includes liability insurance covering any damage that occurs during installation, a protection absent from DIY approaches. Additionally, many manufacturer warranties require professional installation to remain valid, potentially creating costly complications if DIY installations experience problems.

DIY installation appeals to mechanically inclined homeowners comfortable with power tools, ladder work, and following detailed instructions. Modern garage door openers from reputable manufacturers include comprehensive installation manuals with step-by-step guidance, and numerous video tutorials provide visual guidance through challenging steps. The process requires common tools including drills, wrenches, levels, and measuring tapes—equipment most homeowners already possess. Time investment typically runs 4-6 hours for first-time installers, with subsequent installations proceeding faster as familiarity develops.

Critical safety considerations for DIY installation:

- Spring tension dangers: Garage door springs store lethal amounts of energy; never attempt spring adjustment without proper tools and training

- Electrical safety: Ensure circuit breaker is off when connecting power; verify proper grounding to prevent shock hazards

- Ladder stability: Use appropriate ladder height and maintain three-point contact; ceiling mounting requires stable platform

- Weight management: Power head units weigh 30-50 pounds; recruit helper for overhead positioning to prevent drops

- Door testing: After installation, test emergency release mechanism and auto-reverse safety features multiple times

- Hardware torque: Over-tightening mounting bolts can crack ceiling joists or strip threads; follow manufacturer specifications

The complexity difference between chain and belt drive DIY installation remains minimal for most homeowners, though belt tensioning requires additional attention to achieve manufacturer specifications. Chain drives offer more forgiveness in tension settings, allowing functional operation across a broader adjustment range. Belt systems demand precision to prevent slippage without over-stressing belt material, and some homeowners struggle achieving proper tension without experience or specialized tools. Several manufacturers now include tension gauges or detailed adjustment instructions specific to their belt systems, reducing this challenge considerably. Reading product reviews focused on installation difficulty helps identify models known for DIY-friendly design versus those better suited to professional installation.

The warranty implications of DIY installation deserve careful consideration, as they vary significantly among manufacturers and can impact long-term ownership costs. Some brands like Chamberlain and Genie maintain full warranty coverage regardless of installation method, provided the opener is installed according to manual specifications. Other manufacturers, particularly in the premium market segment, restrict full warranty protection to professionally installed units, offering limited coverage for DIY installations. This distinction can represent hundreds of dollars in potential repair costs if major components fail during the warranty period. Homeowners should carefully review warranty terms before committing to DIY installation, particularly for belt drive systems where component replacement costs exceed chain drive alternatives.

Top Brands and Model Recommendations

The garage door opener market features several dominant manufacturers, each offering both chain and belt drive options across multiple price points and feature sets. LiftMaster, owned by the Chamberlain Group, stands as the industry leader and preferred choice of professional installers, commanding approximately 40% market share in North America. Their chain drive models like the 8500W and belt drive units like the 8550WLB represent benchmark products against which competitors measure themselves. LiftMaster pioneered MyQ smart home integration, battery backup systems, and Security+ 2.0 rolling code technology, innovations that eventually became industry standards. Their products consistently earn high reliability ratings from consumer testing organizations and professional installer surveys.

Chamberlain, also under the Chamberlain Group umbrella but marketed as a consumer brand through retail channels, offers excellent value propositions with features nearly identical to LiftMaster products at slightly lower price points. The Chamberlain B970 belt drive and C450 chain drive models provide Wi-Fi connectivity, battery backup, and smartphone control at $50-100 less than equivalent LiftMaster units. This brand serves homeowners comfortable with DIY installation and seeking modern features without premium pricing. The shared engineering and manufacturing between LiftMaster and Chamberlain ensures consistent quality across both brands, with the primary differences being distribution channels and included accessories rather than fundamental performance.

Genie, the second-largest manufacturer, differentiates itself through proprietary technologies like TriloXL chain designs that reduce noise in their chain drive models and specialized belt compounds in their SilentMax series. Genie products typically cost 10-15% less than equivalent LiftMaster offerings while delivering comparable performance and reliability. Their model numbering system clearly delineates feature levels: the 2000 series represents basic functionality, 3000 series adds Wi-Fi and battery backup, and 4000 series includes premium features like programmable vacation modes and advanced security protocols. Professional installers report satisfaction with Genie reliability, though some note that replacement part availability can lag behind LiftMaster’s extensive distribution network.

Recommended models by application:

Budget-conscious chain drive:

- Chamberlain C450: $180-220, basic Wi-Fi, reliable operation, 1/2 HP

- Genie 2042-TKV: $150-190, strong lift capacity, includes two remotes

Mid-range chain drive:

- LiftMaster 8500W: $300-350, wall-mount design saves ceiling space, ultra-quiet for chain drive

- Chamberlain WD962KEV: $250-300, battery backup, MyQ enabled, motion-sensing LED lighting

Premium belt drive:

- LiftMaster 8550WLB: $450-550, 1.25 HP, elite series, built-in camera option, excellent noise dampening

- Chamberlain B970: $350-450, battery backup, smartphone control, ultra-quiet operation

Budget belt drive:

- Genie SilentMax 1000: $250-300, 3/4 HP, reduced noise, basic smart features

- Craftsman 54918: $220-280, reliable operation, limited smart features but solid construction

The emergence of smart home integration as standard rather than premium feature has transformed product expectations across all price points. Models lacking Wi-Fi connectivity and smartphone control now struggle to compete even in budget categories, as consumers expect these capabilities regardless of drive type. This democratization of technology means homeowners can access sophisticated features like geofencing, activity notifications, and voice control without necessarily choosing premium products. However, distinctions remain in integration quality, app reliability, and compatibility with broader smart home ecosystems, areas where LiftMaster’s MyQ platform maintains advantages through partnerships with Amazon, Google, and vehicle manufacturers.

The commercial and heavy-duty opener segment deserves mention for homeowners with exceptionally heavy doors or those seeking maximum durability. LiftMaster 8360W and Genie PowerMax 1500 represent professional-grade products designed for high-cycle applications, typically featuring 1+ HP motors, reinforced drive systems, and extended warranties. These units cost $400-600 before installation but deliver performance margins that ensure longevity under demanding conditions. Homeowners with solid wood doors, oversized openings, or those expecting particularly heavy use (5+ cycles daily) should consider these commercial-grade units regardless of whether they choose chain or belt drive configurations.

Safety Features and Regulations for Garage Door Openers

Modern garage door openers incorporate extensive safety systems mandated by federal regulations and industry standards, with requirements applying equally to chain and belt drive mechanisms. The UL 325 standard, established by Underwriters Laboratories and adopted by the Consumer Product Safety Commission, requires all garage door openers manufactured since 1993 to include automatic reversal systems that detect obstructions and reverse door direction immediately. This primary safety feature operates through two mechanisms: force sensors within the motor assembly that detect increased resistance, and photo-eye sensors positioned near the floor that create an invisible beam across the door opening. If either system detects an obstruction, the door stops and reverses, preventing crushing injuries to people, pets, or vehicles.

The photo-eye sensor system consists of two units mounted on opposite sides of the garage door opening, typically 4-6 inches above the floor. One unit emits an infrared beam while the other receives it, and any interruption of this beam during door closing triggers immediate reversal. Proper alignment of these sensors proves critical for reliable operation, and they require periodic cleaning to remove dust, spider webs, or other debris that can block the beam. Both chain and belt drive systems utilize identical photo-eye technology, meaning safety performance depends on proper installation and maintenance rather than drive mechanism type. Homeowners should test these sensors monthly by deliberately breaking the beam during door closing to verify proper function.

Mandatory safety features on all modern openers:

- Auto-reverse mechanism: Detects resistance and reverses within 2 seconds of contact

- Photo-eye sensors: Prevents closing when beam is broken; required since 1993

- Manual release handle: Emergency disconnect allowing manual door operation during power failure

- Rolling code technology: Prevents code grabbing and unauthorized access

- Force adjustment controls: Allows proper calibration for door weight and resistance

- Timer-to-close warning: Audible signal before automatic closing (where enabled)

- Vacation mode: Disables all remote access while maintaining wall button operation

The emergency release mechanism, typically a red handle hanging from the trolley, represents another critical safety feature that allows manual door operation when power fails or the opener malfunctions. This cord disengages the trolley from the drive system, enabling homeowners to manually lift the door even if the opener cannot function. However, this feature introduces a security vulnerability, as intruders can potentially access this release through gaps in doors using specialized tools.

Modern security enhancements include shield attachments that protect the release mechanism from exterior access and automatic re-engagement systems that reconnect the trolley when door reaches the closed position. These improvements function identically on chain and belt drive systems, residing in the trolley assembly rather than the drive mechanism itself.

Child safety considerations extend beyond mechanical protections to include control system design and mounting specifications. Wall-mounted control buttons must be installed at least 5 feet above the floor, preventing young children from operating the door without adult supervision. Many modern systems include vacation mode settings that disable all remote controls while allowing wall button operation, and some premium models offer parental controls through smartphone apps that restrict operation during specified hours. The emphasis on preventing child injuries from garage doors reflects tragic incidents that prompted regulatory evolution, and current systems demonstrate dramatically improved safety records compared to pre-1993 openers still operating in older homes.

Regular safety testing and maintenance ensure that protection systems function reliably throughout the opener’s lifespan. Homeowners should perform monthly tests of auto-reverse features by placing a 2×4 board flat on the floor in the door’s path during closing. The door should reverse immediately upon contact without excessive force. Photo-eye sensors require monthly testing by deliberately breaking the beam during door closing to verify immediate reversal. Force adjustment settings may require periodic recalibration as door balance changes over time or as springs age and lose tension. Professional annual inspections can identify degraded safety performance before failures occur, providing peace of mind particularly in households with children or pets who spend time in the garage.

Energy Efficiency and Environmental Impact

The energy consumption of garage door openers represents a relatively minor component of household electricity usage, but efficiency considerations still merit attention in an era of rising utility costs and environmental consciousness. Modern garage door openers, whether chain or belt drive, consume approximately 350-600 watts during active operation, translating to roughly 0.15-0.25 kWh per complete door cycle. With average residential garage doors cycling 3-5 times daily, annual operational energy consumption typically ranges from 35-45 kWh annually, costing approximately $4-6 in most regions at average electricity rates. However, standby power consumption—the electricity drawn when the opener idles in ready mode—can actually exceed operational consumption depending on opener age and design.

Older garage door openers manufactured before 2005 often draw 5-10 watts continuously in standby mode, accumulating 44-88 kWh annually just waiting for activation signals. This phantom load costs $5-10 annually while providing no useful function, essentially doubling the opener’s energy footprint. Modern openers engineered for efficiency reduce standby consumption to under 2 watts, sometimes as low as 0.5 watts through improved power supply design and intelligent sleep modes. Energy Star certification for garage door openers requires standby power below 2 watts, making this designation a reliable indicator of efficient models. Both chain and belt drive systems achieve these efficiency standards equally, as power consumption depends primarily on motor design and control board engineering rather than drive mechanism type.

Energy consumption comparison:

| Opener Type | Active Operation (per cycle) | Standby Mode (continuous) | Annual Total | Approximate Annual Cost |

|---|---|---|---|---|

| Pre-2005 chain drive | 0.25 kWh | 7 watts | 105 kWh | $12-15 |

| Modern chain drive | 0.18 kWh | 1.5 watts | 49 kWh | $5-7 |

| Pre-2005 belt drive | 0.22 kWh | 6 watts | 95 kWh | $11-13 |

| Modern belt drive | 0.17 kWh | 1.2 watts | 45 kWh | $5-6 |

| DC motor (either drive) | 0.13 kWh | 0.5 watts | 33 kWh | $3-5 |

DC motor technology represents the cutting edge of garage door opener efficiency, available in both chain and belt drive configurations from premium manufacturers. Unlike traditional AC motors that run at constant speed, DC motors vary speed dynamically based on load requirements, consuming less power when lifting lighter doors or operating under optimal conditions. These intelligent motors also enable softer starts and stops, reducing stress on door components and mechanical assemblies while improving longevity.

The efficiency gains can reduce energy consumption by 30-50% compared to conventional AC motors, though DC motor systems typically cost $100-150 more than equivalent AC models. For homeowners prioritizing environmental impact and operating cost minimization, DC motor openers represent the optimal choice regardless of whether they feature chain or belt drives.

The environmental impact of manufacturing and disposing of garage door openers extends beyond operational energy consumption. Chain drive systems utilize more metal components, primarily steel in the chain assembly and sprockets, while belt drives incorporate rubber compounds and synthetic reinforcement materials. Steel production carries significant environmental costs through mining, smelting, and manufacturing processes, though steel’s recyclability partially offsets these impacts. Modern rubber belt compounds present recycling challenges, as composite materials resist separation into constituent components for reprocessing. However, the longer service life of both systems—typically 15-20 years—means that manufacturing impact amortizes over extensive use periods, making operational efficiency and longevity more environmentally significant than material choice.

Battery backup systems, increasingly common on modern openers, introduce environmental considerations through battery production and disposal requirements. Most backup systems use sealed lead-acid batteries similar to automotive batteries, which contain toxic materials requiring proper recycling through certified facilities. These batteries typically last 3-5 years before replacement becomes necessary, adding recurring environmental impact throughout the opener’s lifespan. However, the convenience and safety benefits of maintaining garage access during power outages generally outweigh environmental concerns for most homeowners. Some manufacturers now offer lithium-ion battery backup options that provide longer life spans and reduced environmental impact, though at premium prices reflecting higher manufacturing costs.

Integration with Home Security Systems

Garage door openers increasingly function as integral components of comprehensive home security ecosystems, with integration capabilities extending far beyond simple remote operation. Modern security system platforms from providers like ADT, SimpliSafe, and Vivint now incorporate garage door status monitoring as standard features, alerting homeowners when doors remain open unexpectedly or open during unusual hours. This integration works equally well with chain and belt drive openers, as the connectivity occurs through the electronic control system rather than mechanical components. The ability to verify garage door status remotely provides peace of mind when traveling or during the workday, addressing one of homeowners’ most common security anxieties.

The vulnerability of garage doors as entry points for burglaries has driven innovation in security-focused features across both chain and belt drive systems. Statistics from law enforcement agencies indicate that garages represent the entry point in approximately 9% of home burglaries, often through exploiting weak door-to-house connections or older opener technology susceptible to code-grabbing. Modern rolling code technology addresses the code-grabbing vulnerability by generating new access codes with each operation, rendering intercepted signals useless for subsequent access attempts. Some premium systems now incorporate two-factor authentication for smartphone-based access, requiring both possession of the authorized device and entry of a PIN code for remote operation, dramatically increasing security against unauthorized access.

Security vulnerabilities and mitigations:

Common security risks:

- Emergency release exploitation through door gaps

- Old fixed-code remotes vulnerable to code grabbing

- Unsecured wall-mounted control panels accessible through windows

- Automatic closing timer-to-close features that telegraph patterns

- Universal remote compatibility allowing unauthorized pairing

Effective security enhancements:

- Install emergency release shield to prevent exterior access

- Upgrade to Security+ 2.0 or equivalent rolling code systems

- Enable vacation mode when traveling for extended periods

- Use randomized auto-close timers to prevent pattern recognition

- Disable learn button access or protect with PIN code

- Install security cameras with garage door field of view

The integration between garage door openers and vehicle systems represents an emerging frontier in smart home technology, with several automobile manufacturers incorporating garage control into vehicle infotainment systems. Chevrolet, Buick, and Cadillac vehicles equipped with myChevrolet mobile app can operate MyQ-enabled garage door openers automatically as vehicles approach homes using geofencing technology. Similar capabilities exist in premium vehicles from Mercedes-Benz and BMW through their connected car platforms. These integrations function identically with chain and belt drive openers, requiring only MyQ compatibility in the opener regardless of drive mechanism. The convenience of never needing physical remote controls appeals to technology-forward homeowners, though security implications require careful consideration regarding vehicle theft scenarios.

The proliferation of delivery services introducing products like Amazon Key In-Garage Delivery adds another dimension to garage door security considerations. These services enable delivery personnel to access garages temporarily for package placement, protecting parcels from weather and theft while reducing delivery failures from homeowner absence. The technology utilizes cloud-based temporary access codes generated specifically for authenticated delivery personnel during scheduled delivery windows, with the system automatically revoking access after package placement. Surveillance requirements mandate that delivery personnel wear body cameras during garage access, and homeowners receive notifications with video verification of deliveries. This capability works with MyQ-enabled openers of both chain and belt drive configurations, representing a convenience feature valued by frequent online shoppers.

Physical security considerations extend to the garage-to-house door, often representing a weaker security element than the garage door itself. Many homeowners invest in high-quality garage door openers and neglect the interior door, which may feature hollow-core construction and inadequate locks. Security professionals recommend treating garage-to-house doors as primary entry points, installing solid-core doors, deadbolt locks, and considering smart locks for additional access control and monitoring. The security effectiveness of sophisticated garage door openers diminishes significantly if intruders can easily breach the interior door after gaining garage access through other means like damaged panels or forced windows.

Troubleshooting Common Issues with Chain and Belt Drive Systems

Understanding common problems affecting garage door openers enables homeowners to address minor issues without professional service calls, potentially saving hundreds of dollars in diagnostic and repair fees over the opener’s lifespan. Chain drive systems frequently experience issues related to lubrication and tension, with symptoms including excessive noise, jerky operation, or complete failure to move the door. When a chain drive opener operates noisily or inconsistently, the first troubleshooting step involves inspecting chain tension—the chain should have approximately 1/4 to 1/2 inch of slack at its midpoint. Excessive slack indicates chain stretch or loose mounting hardware, while insufficient slack suggests over-tightening that stresses motor components and accelerates wear.

Belt drive troubleshooting begins with similar inspection protocols but requires attention to different failure modes. Belt slippage represents the most common issue, typically manifesting as the motor running while the door moves partially or not at all. This problem usually stems from inadequate belt tension, contamination on the belt surface reducing friction, or worn pulleys that can no longer grip effectively. Unlike chains that telegraph impending failure through gradually increasing noise, belts sometimes fail suddenly through complete breakage, particularly in systems experiencing frequent temperature cycling that fatigues belt materials. Visual inspection for cracks, fraying, or glazing on the belt surface can identify developing problems before catastrophic failure occurs.

Diagnostic troubleshooting guide:

Problem: Opener runs but door doesn’t move

- Chain drive: Check for broken chain, loose mounting, excessive slack

- Belt drive: Inspect for belt slippage, broken belt, loose pulley

- Both: Verify trolley engagement, check emergency release position

Problem: Door reverses immediately after touching floor

- Check photo-eye sensor alignment and cleanliness

- Adjust force settings (closing force may be set too light)

- Inspect for obstructions in door track or threshold

- Verify proper door balance and spring tension

Problem: Remote controls don’t work

- Replace remote batteries (most common cause)

- Re-program remotes to opener using learn button

- Check for radio interference from LED lights or electronics

- Verify opener antenna is properly extended and positioned

Problem: Excessive noise during operation

- Chain drive: Lubricate chain, tighten loose hardware, adjust chain tension

- Belt drive: Check for debris between belt and pulley, inspect for bearing wear

- Both: Lubricate door hinges and rollers, verify proper door balance

Problem: Door stops mid-cycle

- Adjust travel limit switches (up and down limits)

- Check for binding in door tracks or worn rollers

- Verify adequate motor power for door weight

- Inspect for obstruction detection false triggers

Electronic control board failures represent problems common to both drive types that often confuse homeowners attempting diagnosis. Symptoms include erratic behavior, failure to respond to commands, or lights functioning while motor doesn’t engage. Many modern openers feature diagnostic LED indicators that flash coded patterns corresponding to specific problems, and consulting the owner’s manual to interpret these codes can identify issues precisely. Common electronic failures include surge damage from lightning strikes or power fluctuations, component aging causing capacitor failures, or moisture infiltration corroding circuit connections. Surge protectors installed on garage electrical circuits prevent many electronic failures and represent wise investments given that control board replacements typically cost $100-200.

The photo-eye sensor system causes numerous service calls despite simple solutions for most problems. Misalignment represents the most frequent issue, occurring when sensors are bumped by parking vehicles, lawn equipment, or accidental impact. The sensors must align precisely for the infrared beam to register properly, requiring only slight adjustment of mounting brackets to restore function. Dust, spider webs, or moisture condensation on sensor lenses also interrupt beam transmission, with simple cleaning immediately resolving these problems. Sunlight interference affects some sensor models during specific times of day when direct sunlight overwhelms the infrared beam, typically requiring repositioning of sensors or installation of sunshades to prevent false triggers.

Professional diagnostic service becomes necessary when problems exceed homeowner troubleshooting capabilities or when safety concerns exist. Attempting repairs on spring assemblies, for example, poses serious injury risks and should always involve trained technicians with proper tools. Similarly, electronic problems requiring circuit board component replacement or motor armature service exceed most homeowners’ capabilities and justify professional assistance. Understanding which problems permit DIY resolution versus those requiring professional service helps homeowners make cost-effective decisions while maintaining safety and system reliability.

Comparing Chain vs Belt Drive Garage Door Opener Costs Across Brands

Price transparency in the garage door opener market varies significantly across distribution channels, with professional installer pricing, big-box retailer costs, and online marketplace rates differing substantially for identical models. Understanding these pricing dynamics helps consumers identify the best value propositions when comparing chain and belt drive options across major brands. Professional installers typically quote package prices including both equipment and labor, with markups on hardware ranging from 20-40% above direct retail prices. This premium compensates for warranty service obligations, inventory costs, and professional expertise, but creates opportunities for savings through separate equipment purchase and installation scheduling.

Big-box retailers like Home Depot and Lowe’s position themselves as middle-ground options, offering direct equipment purchase at competitive prices with installation available through contractor networks. These retailers frequently run promotional events reducing opener prices by $50-100, particularly during spring and fall when garage door projects peak. The Chamberlain and Craftsman brands dominate big-box shelf space, with LiftMaster models typically available through special order rather than floor stock. This distribution strategy reflects market segmentation, with consumer brands targeting DIY customers through retail while professional brands focus on installer channels. Understanding these dynamics helps shoppers navigate between equivalent products under different brand names but identical engineering.

Price comparison across purchase channels:

| Model Type | Professional Installer | Big Box Retail | Online Marketplace | Price Range |

|---|---|---|---|---|

| Basic chain drive | $400-500 installed | $150-200 + install | $130-180 + shipping | $280-500 |

| Mid-range chain drive | $550-700 installed | $250-350 + install | $220-300 + shipping | $420-700 |

| Basic belt drive | $600-750 installed | $250-350 + install | $220-300 + shipping | $470-750 |

| Premium belt drive | $800-1000 installed | $400-550 + install | $350-500 + shipping | $600-1000 |

Online marketplaces including Amazon, eBay, and manufacturer direct websites offer the lowest equipment prices but shift installation responsibilities and warranty considerations to consumers. Amazon particularly dominates online sales through competitive pricing, extensive customer reviews, and convenient delivery options including free shipping for Prime members. However, manufacturer warranties sometimes differ for marketplace purchases versus authorized dealer sales, and some manufacturers explicitly void warranties on gray-market products purchased through unauthorized resellers. Careful verification of seller authorization status and warranty terms protects consumers from false economy through discounted products lacking full manufacturer support.

Seasonal pricing patterns affect both chain and belt drive garage door openers, with the most significant discounts occurring during promotional periods surrounding major holidays. Memorial Day, Independence Day, and Labor Day typically feature aggressive pricing on home improvement products including garage door openers, with discounts reaching 25-35% off regular retail prices. Black Friday and Cyber Monday sales events extend these promotional periods into late November, offering additional savings opportunities. Smart consumers planning garage door opener purchases can achieve substantial savings by timing purchases to coincide with these events, particularly for premium belt drive systems where percentage discounts translate to larger absolute savings.

The total cost of ownership calculations should incorporate not just purchase and installation costs but also anticipated maintenance expenses, energy consumption, and potential repair costs over the system’s expected lifespan. When analyzed comprehensively, belt drive systems often demonstrate superior value despite higher initial costs, particularly for homeowners prioritizing noise reduction and minimal maintenance obligations. Chain drives remain more economical for budget-conscious installations where upfront cost minimization takes priority over long-term convenience. Neither option represents a universally superior value proposition—optimal choice depends on individual circumstances, priorities, and budget constraints balanced against expected benefits over 15-20 year service lives.

Noise Comparison: Real-World Measurements and Impact

Quantifying the noise difference between chain and belt drive garage door openers through controlled measurements provides objective data to supplement subjective user experiences. Sound meter testing conducted in standardized residential garage environments reveals that chain drive openers generate peak noise levels of 78-85 decibels measured three feet from the operating mechanism, with average sustained noise during door travel measuring 75-80 decibels. These measurements place chain drive operation in the same acoustic range as vacuum cleaners, garbage disposals, or alarm clocks at close range. The sound character includes distinct metallic clicking and grinding components at frequencies that penetrate walls effectively, explaining why chain drive noise transmission to adjacent rooms proves particularly noticeable.

Belt drive garage door systems measure significantly quieter in controlled testing, with peak noise levels reaching only 65-72 decibels and sustained operation averaging 60-68 decibels at three-foot measurement distance. This 10-15 decibel reduction translates to approximately 50% less perceived loudness due to the logarithmic nature of decibel scales. More importantly, belt drive noise characteristics differ qualitatively from chain drives, featuring predominantly lower frequencies with less metallic content that transmit through building structures less effectively. The combination of reduced amplitude and different frequency composition results in noise that seems even quieter than raw decibel measurements suggest, with many users reporting belt drives as “almost silent” despite measurable sound generation.

Noise transmission through common building materials:

| Material/Construction | Chain Drive Transmission | Belt Drive Transmission | Noise Reduction |

|---|---|---|---|

| Open air (no barriers) | 75-80 dB | 60-68 dB | 15-20 dB |

| Standard drywall (single layer) | 65-70 dB | 50-58 dB | 15-18 dB |

| Insulated wall (R-13) | 55-62 dB | 42-50 dB | 13-18 dB |

| Concrete floor/ceiling | 60-68 dB | 48-55 dB | 12-15 dB |

| Wooden floor joists | 68-75 dB | 55-62 dB | 13-15 dB |

The impact of garage door opener noise on household quality of life varies dramatically based on home layout and occupant schedules. Single-story homes with attached garages but no living spaces directly above experience minimal disruption from chain drive noise, as even standard insulated interior walls attenuate sound sufficiently for comfortable living. Two-story homes present more challenging acoustic scenarios, particularly when master bedrooms or children’s rooms sit directly above garages. In these configurations, chain drive vibration transmits through ceiling joists and structural framing, sometimes causing sympathetic vibration in bedroom furniture, picture frames, or light fixtures that amplifies perceived disturbance beyond the opener’s direct noise contribution.

Time-of-day considerations amplify noise concerns for households with non-traditional schedules. Families with members working night shifts or early morning commutes face particular challenges from noisy garage door openers, as departures or arrivals during sleeping hours create conflicts between operational necessity and household peace. Belt drive systems address these conflicts effectively, enabling garage access at any hour without disturbing sleeping family members. This capability proves particularly valuable during infant and toddler years when parents become hyperaware of any noise potentially disrupting hard-won sleep schedules. Similar considerations apply to households with pets sensitive to loud mechanical noises, where chain drive operation may trigger barking or anxiety responses that belt drives typically avoid.

Acoustic enhancement strategies can reduce chain drive noise transmission when belt drive upgrades aren’t feasible due to budget constraints or other considerations. Vibration isolation mounts placed between the opener mounting bracket and ceiling joists prevent direct vibration transmission into structural framing, potentially reducing noise transmission by 5-8 decibels. Sound-dampening materials applied to garage ceiling surfaces absorb acoustic energy before it transmits into living spaces, though effectiveness varies based on material type and installation quality. These modifications rarely match belt drive quietness but can improve chain drive acceptability in noise-sensitive applications for $50-150 in materials plus installation labor, representing cost-effective compromise solutions for budget-conscious homeowners.

FAQ: Chain vs Belt Drive Garage Door Openers

What is the main difference between chain vs belt drive garage door openers?

The primary difference between chain and belt drive garage door systems lies in the mechanism used to lift the door. Chain drives use a metal chain similar to a bicycle chain, while belt drives employ a reinforced rubber belt. This fundamental distinction affects noise levels, maintenance requirements, and initial cost. Chain drives operate louder, typically producing 75-85 decibels, but cost $150-250 less initially. Belt drives run much quieter at 60-70 decibels and require less maintenance but command higher upfront prices. Both systems offer comparable durability and lifting capacity for standard residential applications.

Are belt drive garage doors worth the extra cost?